This brief 2-page medical guide will provide you will the medical parts, processes and tools recommended, when working with Jet Spindles. Covering the most popular applications, the guide gives you the critical selling points, as well as a comparison to competing technologies, based on installation, setup, runout and pricing details.

- Home

- /

- Small Cutting Tools

BLOG

Jet Spindles Industry Guide – Medical

NEW – Jet Spindles Presale & Quick Start Guide

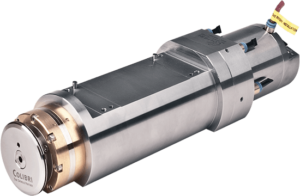

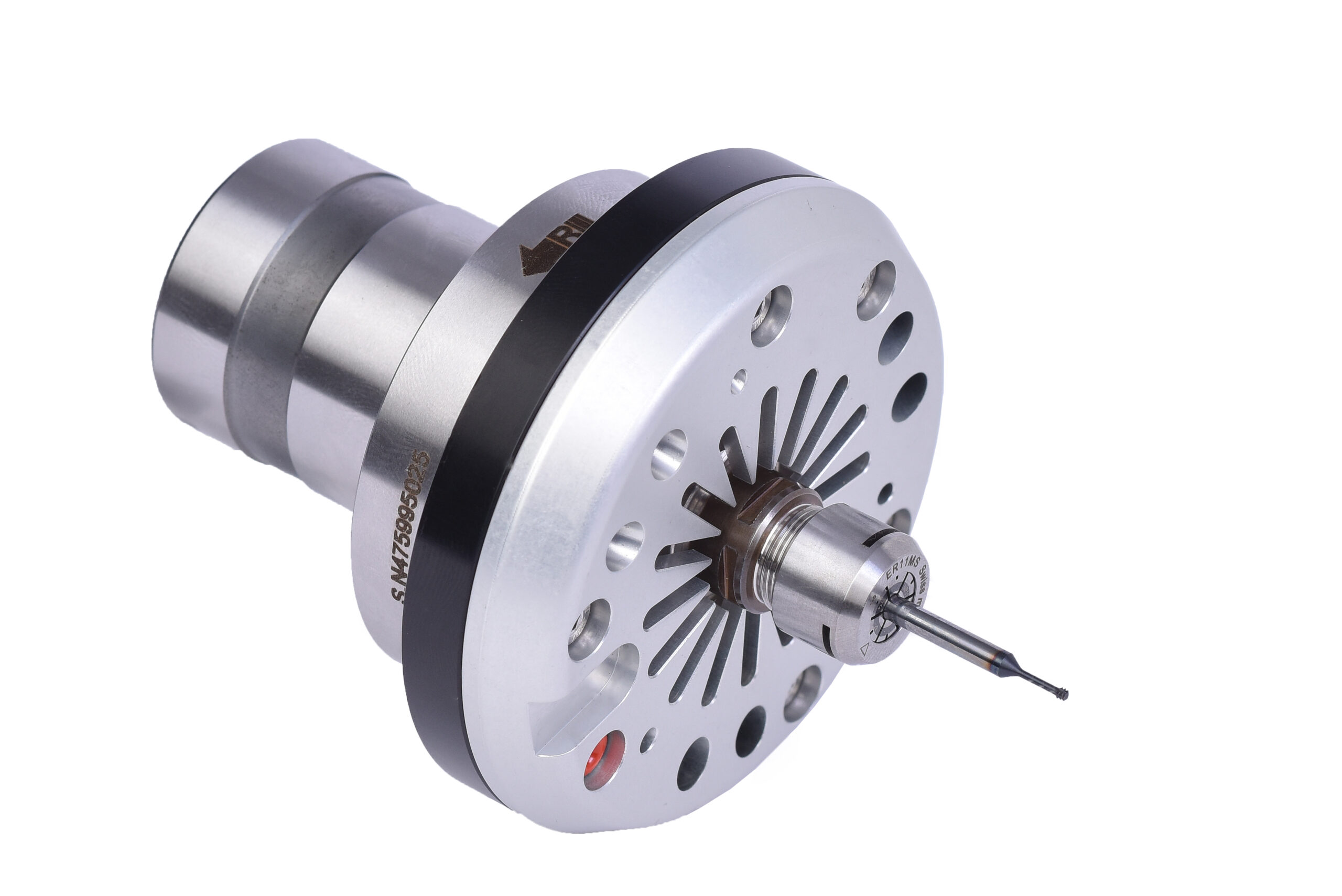

This new comprehensive guide provides Colibri Jet Partners with a valuable document to guide the sales personnel through the jet spindle sales process. The guide supports the salesperson in identifying the correct jet spindle for the customers’ application by covering all the possibilities and options that need to be addressed in determining the best jet spindle and operating parameters for the job.

NEW – Jet Spindles Presale Guide

The NEW May 2022 Jet Spindles Presale Guide is our latest official Presale Guide for Colibri Partners. The Presale Guide provides a focused yet comprehensive guide to our jet products family. The Presale Guide, which is very visual, includes an updated working zone chart and recommended tool sizes for various metal groups. Please get in touch with us with your local branding and translation needs.

ISCAR SPINJET MICRO90 NPA

On March 13th, ISCAR released the SPINJET MICRO90 NPA with a stunning interactive announcement document. A lot of hard work has gone into this new product announcement. You will notice that the document is detailed and informative and includes detailed recommended cutting conditions, by material, application, and machine high-pressure coolant pressure.

Tier 1 Case Study – Engraving & Chamfering

We are extremely excited about TaeuguTec’s, Mr. Lacayo’s achievements in bringing traceability, flexibility, productivity, ROI, cost-saving, quality with the HPC Jet Spindle and we want to personally thank him for sharing the above information that we can share with all our partners. There are many industries where such engraving and chamfering opportunities can be found, such as the motor vehicle and aerospace parts industries.

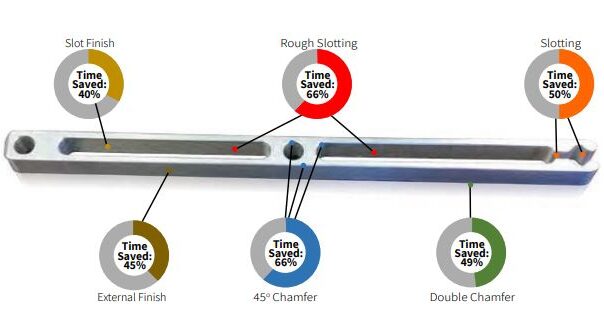

Jet Spindle Application Insights: Slot Milling

SPINJET Case Studies – ISCAR Slovakia covers two case studies completed at the same Customer, LOMAN. The first article focused on the case study involving the chamfering of an aluminum plate and this second article focuses on the case study covering the slot milling of stainless steel. Both with the GJET.

Jet Spindle Application Insights: Chamfering

SPINJET Case Studies – ISCAR Slovakia covers two case studies covered at the same Customer, LOMAN. The first case study focused on aluminium plate chamfering and the second case study focuses on stainless steel slotting. Both with the GJET.

Jet Spindle Application Insights: Engraving

Engraving is an ideal application for jet spindles and process time savings of 6-12X can be achieved, which is the equivalent of saving 80-98% saving in machining time!

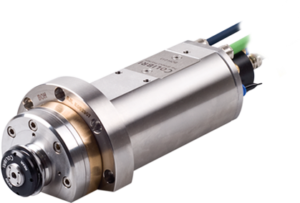

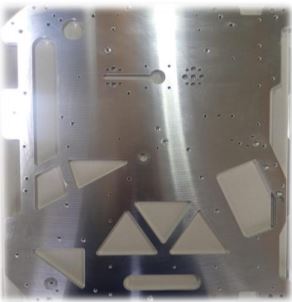

BIG Opportunities – SMALL Tools

Operationally, once the roughing processes are completed on large machines, we need to physically move the rough part to machines that are better equipped to complete the finishing processes efficiently and accurately. This implies a string of additional activities and costs, including additional costly high-speed machines, planning, and machine setup. Ideally, we want to complete all the processing efficiently and accurately on the same large machine and in the same setup. This is much more profitable.

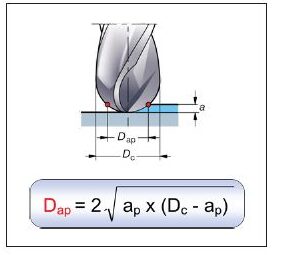

BIG MRR – SMALL Tools

As a reference, when looking at cost of processing a part, machining cycle time is usually 40% of the budget, while the cost of tools (including the costs of Jet Spindles) is usually around 3% of the budget. So, with this in mind, we are primarily concerned with improving cycle times and this article looks at the BIG impact of Material Removal Rates with SMALL Tools, i.e. shorter cycle times with SMALL Tools. Let’s proceed

Latest News

-

09

JulBlog post Jet Spindles Industry Guide – Medical -

09

MayBlog post Jet Spindle Certified Service Centers -

16

FebBlog post WHAT’S NEW at TAEGUTEC? ! -

06

Jun -

07

AprBlog post NEW – Jet Spindles Presale Guide