As part of our March series focusing on jet spindle speeder application insights, we are proud to present these two case studies kindly provided by the Slovakian Office of our Global partner ISCAR.

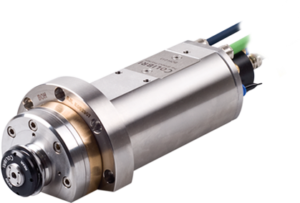

These case studies at the Slovakian manufacturer LOMAN focus on two critical processes that are successfully covered by the ISCAR SPINJET GJET – a Jet Spindle Speeder – designed, developed, and manufactured by Colibri Spindles, ISRAEL.

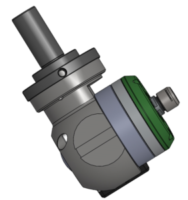

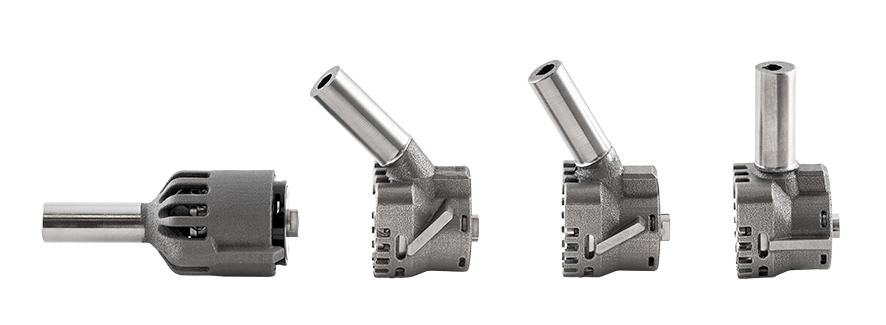

The GJET can high-speed chamfer with 0.1 – 4.0 mm diameter cutting tools as well as a high-speed slot mill with 0.1 – 3.0 mm cutting tools on steel, stainless steel, non-ferrous metals, and superalloys. For full details of the GJET, adaptor options, technical information, downloads, and capabilities, visit our own line catalog

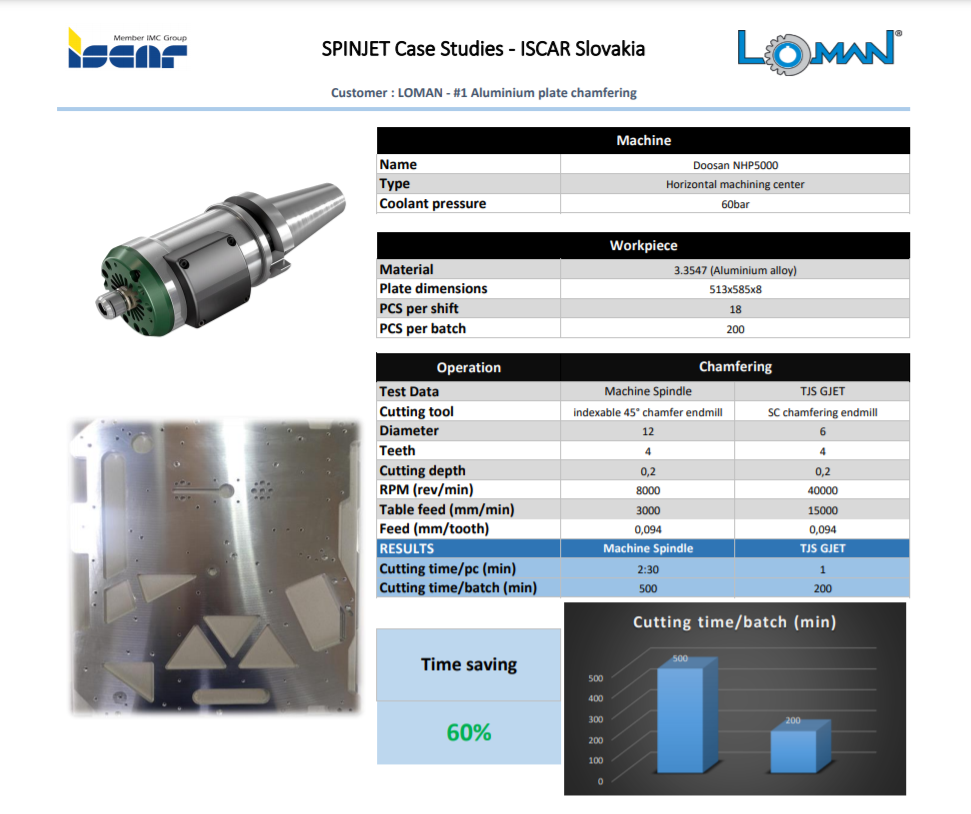

LOMAN, a Slovakian producer, and ISCAR Slovakia Customer has managed to cut their chamfering time by 60%, saving 300 minutes (5 hours) per batch, or in simple terms reducing an 8 1/3 hour process to a 3 1/3 hour process. The SPINJET GJET uses a 6mm diameter SC chamfering endmill – half the size of the standard 12mm indexable 45-degree chamfer endmill. Cutting depth of just 0.2mm is maintained and with an RPM of 5X maximum machine spindle speed, a table feed of 5X is achieved, reaching 15,000 mm/min.

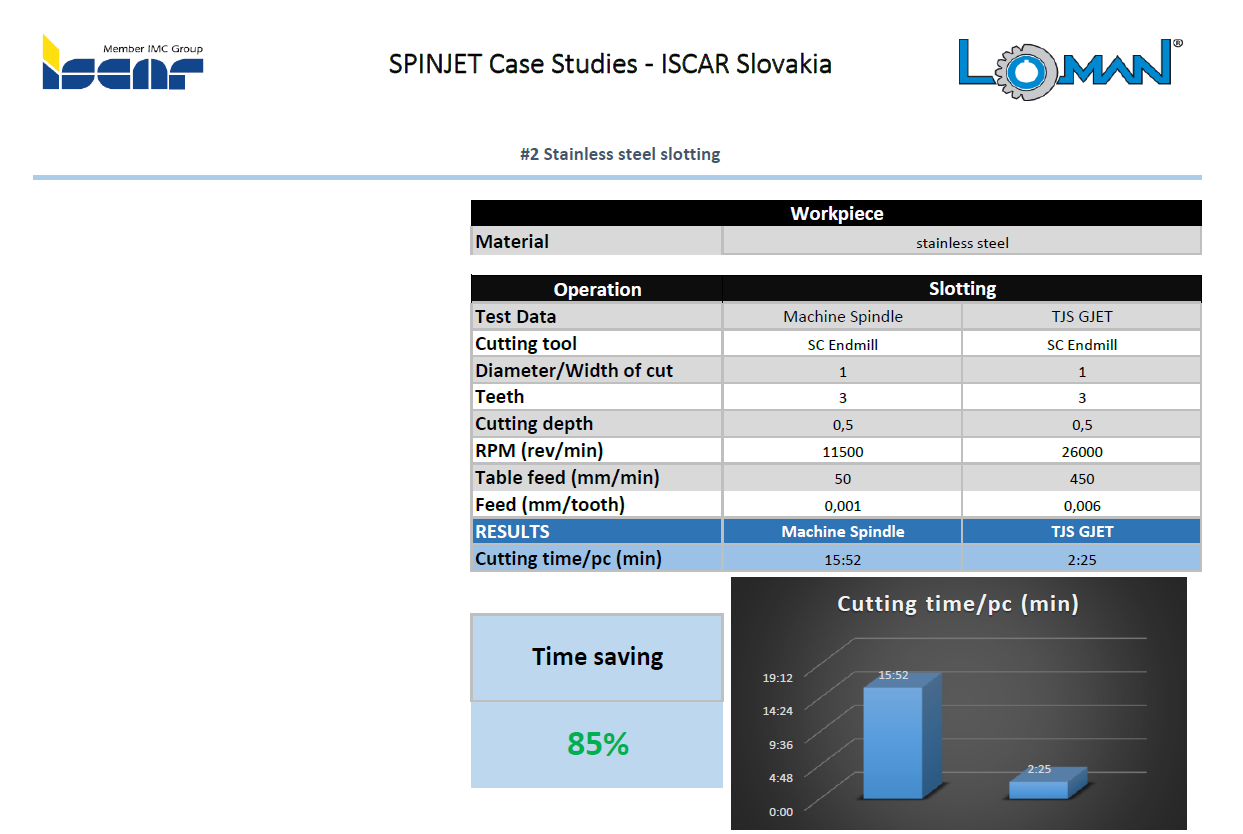

In this second case study, LOMAN was looking to improve the processing time for their slotting operation on stainless steel with dimensions – Ae of 1 mm and Ap of 0.5 mm. Table feed was improved 9X from 50 mm/min to 450 mm/min and the cutting time per pc was successfully reduced from nearly 16 minutes to just under 2 1/2 minutes, a fantastic 85% time-saving!

As a recommendation, we would suggest to LOMAN to use the HPC Jet for the slotting or alternatively reducing the GJET table feed to 400 mm/min to ensure maximum jet spindle speeder lifetime use.

COLIBRI SPINDLES PARTNER

ISCAR Slovakia

ISCAR SLOVAKIA, located in Žilina-Budatín, Slovakia is one of the many offices of ISCAR, founded by Mr. Stef Wertheimer in 1952.

ISCAR subsidiaries and agents cover over 60 countries, with fully staffed offices and technical specialists to meet customer needs. In some of the larger countries, regional offices add extra value by having ISCAR personnel and facilities as close as possible to customer production sites.

Many of the ISCAR branches integrate fully equipped training centers in order to update and instruct customer personnel on the latest metal removal techniques and products. If it is not possible or practical for a group to visit the training center, seminars are held at the customer’s facility. To meet market demands and maintain just-in-time deliveries of specially tailored tools, ISCAR has production facilities in the following countries:

| Europe: France Germany Hungary Italy Slovenia Spain Switzerland Turkey |

Americas: Argentina Brazil United States of America |

| Asia: China Israel S. Korea |

ISCAR is a global company meeting the needs of the industry locally and at every level.

Link to download the SPINJET Case Studies – ISCAR Slovakia

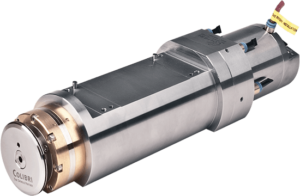

Founded and managed by Mr. Oren Harpaz, Colibri Spindles is an Israeli manufacturer and a world leader in designing, engineering, and manufacturing high-speed precision spindles for the semiconductor industry.

Colibri Spindles is the world leader in HPC, Jet Spindle technology. Colibri Spindles is the first company in the world to develop this technology effectively, commercially.

Colibri Jet Spindles are incorporated in world-leading cutting tool manufacturing.

For more details, contact us or contact one of our esteemed partners.