| CASE STUDY | |

|---|---|

| Industry | Die & Mold |

| Application | Profile Milling |

| Part | Electrode |

| Machine | HAAS VF4 |

| Challenge | Reduce machining time and achieve an improved finish. |

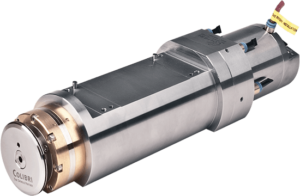

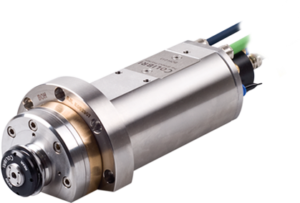

| Solution | Applied GJET for its speed, compactibility and accuracy |

|

|

| OPERATING DATA | 3D Bottle Finish | 3D Slot Finish | ||

|---|---|---|---|---|

| Test Data | Machine Spindle | Jet Spindle | Machine Spindle | Jet Spindle |

| Spindle Speed (rpm) | 10,000 | 25,000 | 10,000 | 24,000 |

| Cutting Speed (VC M/min) | 157 | 393 | 63 | 151 |

| Depth of Cut (mm) | 0.1 | 0.1 | ||

| Width of Cut (mm) | 0.07 | 0.07 | ||

| Table Feed Vf(mm/min) | 2,000 | 5,400 | 800 | 2,000 |

| Machining Time (min) per part | 360 | 183 | 40 | 30 |

| Tool life [wear] – high, average, low | low | high | low | high |

| Surface Finish – high, average, low | low | high | low | high |

| Cycle Time Improvement (%) | 49% | 25% | ||

| Total Machining Time (min) per part | 400 | 213 | ||

| CONDITIONS | ||

|---|---|---|

| Coolant Pressure & Flow rate | 15 bar at 10 liters per minute | |

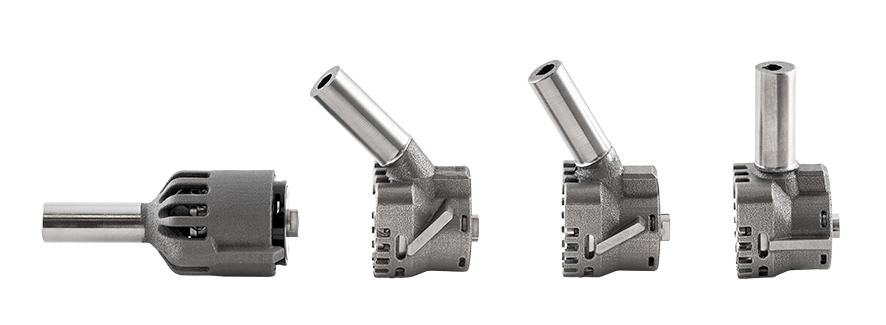

| Holder Type | ER32 | |

| Material & Hardness | Aluminium 6061 | |

| Cutting Tool | Ball nose endmill 5.0 mm – 2 teeth | |

| Diameter (mm) | 5.0 | |

| No. of Teeth | 2 | |

Downloads

no files found

TJS-20K/30K/40K: BT30/40

Downloads

no files found

Downloads

no files found

Downloads

no files found

Industries

Industries