Find/Identify the opportunity

The challenge with developing new sales avenues is in delivering significant value to the customer. For this, you need both a good understanding of the products you are selling and how best to apply them and enough industry knows how to identify the ideal opportunities in your customers’ processes and then deliver them as well.

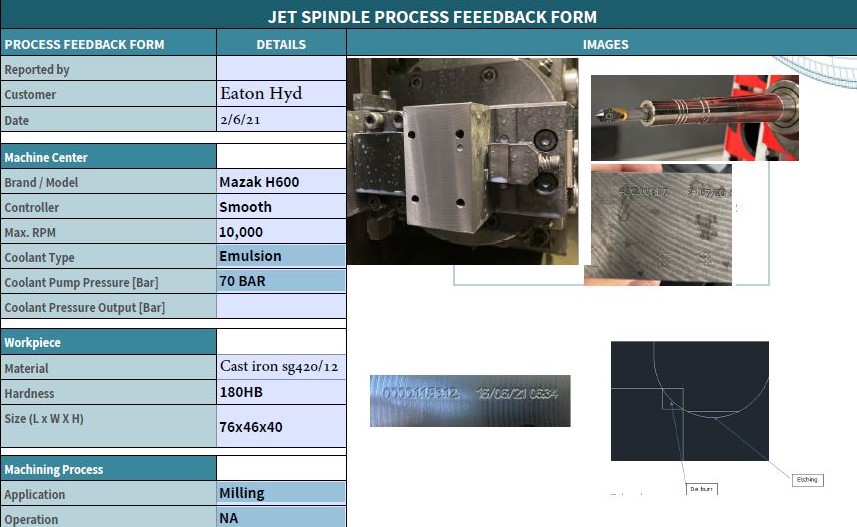

Mr. Iain Lacayo, Technical Sales Engineer at TaeguTec UK Ltd, identified the perfect new sales avenue, at one of their Tier 1 accounts in the UK. The company, a well-established manufacturer of hydraulic valves, was in the process of updating its entire production process to achieve greater flexibility and output. The existing process revolved around a single large rotator machine which was being replaced by multiple Mazak machines with robot loaders and conveyors. As is often the case, not all requirements and features are for seen and in this case, the manufacturer’s QC Team came in with a last-minute requirement that the new process would require full traceability. Each hydraulic value would need to have a unique ID and date and time of production.

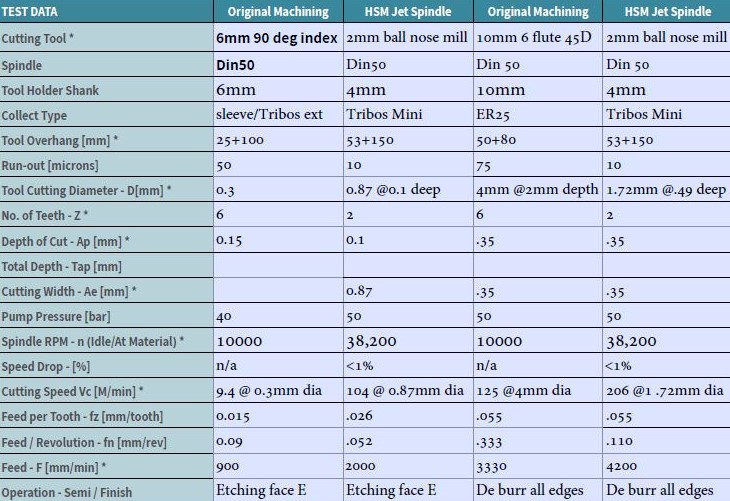

Existing Solution

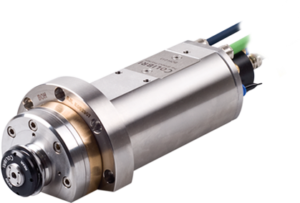

As in all cases, there are always workarounds. In this case, the engraving of the unique part ID and date and time was engraved using the Mazak spindle and expensive small tools. There were several issues with the existing process. It was slow. The hydraulic valves are cut from cast iron (SG Iron), so the new Mazak’s were outfitted with powerful, yet relatively slow spindles. The engraving quality was not high. Engraving and other finishing processes performed on cast iron at low RPMs do not provide a high level of accuracy and finish. Lastly, the process was costly. To overcome the limitations the manufacturer was using expensive tools and replacing them at a high rate.

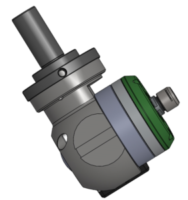

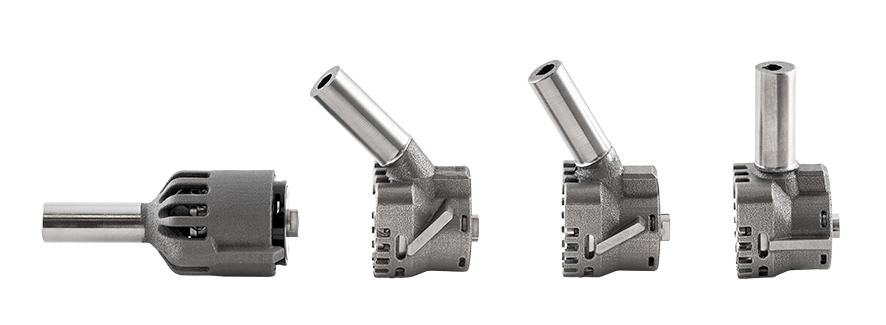

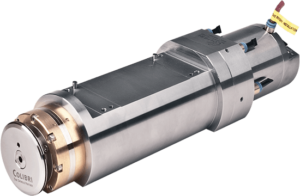

Jet Spindle Solution

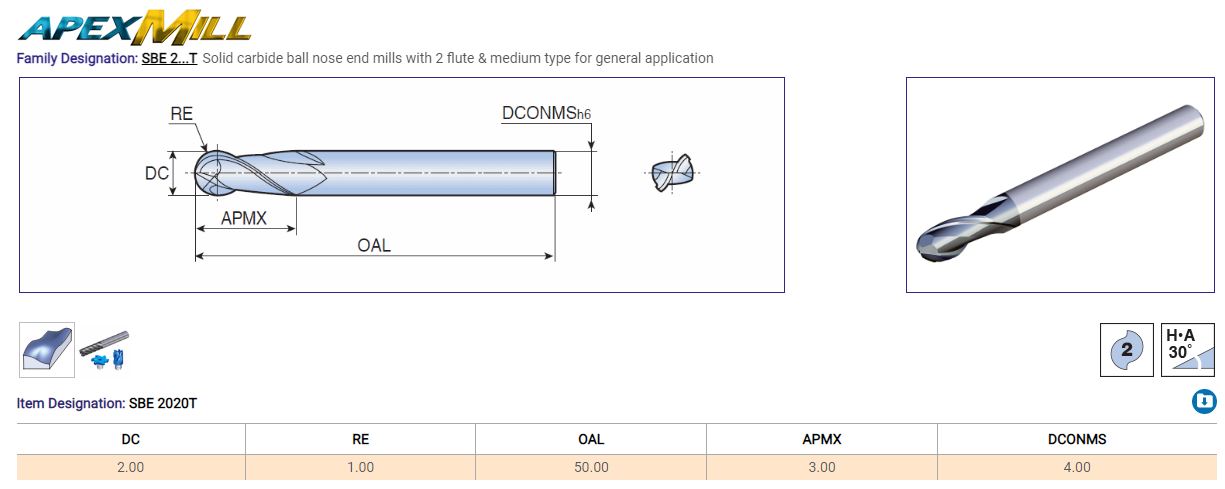

Iain, in consultation with the Colibri Technical Sales Team, recommended the HPC Jets. Powerful enough to easily complete finishing processes on cast iron. Fully able to optimize the new Mazak CNC high-pressure coolant of 1000 PSI (70 Bar). With just a 3-micron run out, able to work extremely accurately and add 3X to 4X times the machine spindle speed provides both fast processes and extended tool life. As a bonus, the HPC Jet Spindles also complete the chamfering process using the same TaeguTec APEXMILL Ball nose mill cutter, saving space in the tool holder and on having to double the number of HPC Jet Spindles.

Mr. Iain Lacayo, Technical Sales Engineer at TaeguTec UK ltd:

“TaeguTec UK was asked by a customer to help improve the productivity on a production line, and after looking at the process we suggested the Typhoon unit which can show massive improvements in cycle time and better surface finish. The customer was spending about 15k a year on two tools. We suggested using a TaeguTec 2mm Ball nose and suggested using the same tool to produce the break edge chamfer which is only 0.2mm. After an extensive test period, we demonstrated the repeatibillity of the Typhoon unit and demonstrated fantastic tool life! We are now changing this process on all the machines at this customer. It was a good project to work on and we worked closely with Oren Harpaz to achieve this result.”

The company purchased one HPC Jet Spindle for each of the machines and is extremely satisfied. Tool life has been significantly improved, providing a massive cost-saving and ROI of 1-2 months. Engraving and chamfering processes are now so efficient and fast that they have brought the full part process time back to the initial planned process time, pre the QC traceability requirement, which for the manufacturer is phenomenal.

Going Forward

Iain, having opened the customer’s door wide open, so now looking into additional TaeguTec productivity improvements for their processes, including the development of maxi rush small barrel mills to provide the customer with additional benefits of faster tool change and even better repeatability.

We are extremely excited about TaeguTec’s, Mr. Lacayo’s achievements in bringing significant traceability, flexibility, productivity, ROI, cost-saving, quality improvements with the HPC Jet Spindle and we want to personally thank Iain for sharing the above information to share with all our partners. There are many industries where such engraving and chamfering opportunities can be found, such as the motor vehicle and aerospace parts industries.

A fantastic example of how focusing on Jet Spindle’s strengths to drive value for customers is the key to successful sales.