The NEW May 2022 Jet Spindles Presale Guide is our latest official Presale Guide for Colibri Partners.

BRANDING & TRANSLATIONS

This is a message to all our global partners and their regional offices to contact us regarding their branded and translated Presale Guide requirements.

The Presale Guide provides a focused yet comprehensive guide to our jet products family. The Presale Guide, which is very visual, includes an updated working zone chart and recommended tool sizes for various metal groups, by product.

This blog post will review and explain the Presale Guide, page-by-page.

HIGH-SPEED MACHINING

The cover page immediate draws the customer’s attention to four key messages:

- We are talking about high-speed machining with jet spindles;

- The variety of adaptors we support;

- The industries used – die & mold, automotive, aerospace, medical and general manufacturing; and

- These are ultra-precision high-speed Jet Spindles for a variety of milling and drilling processes with small tools. Cutting machining time up to 70%.

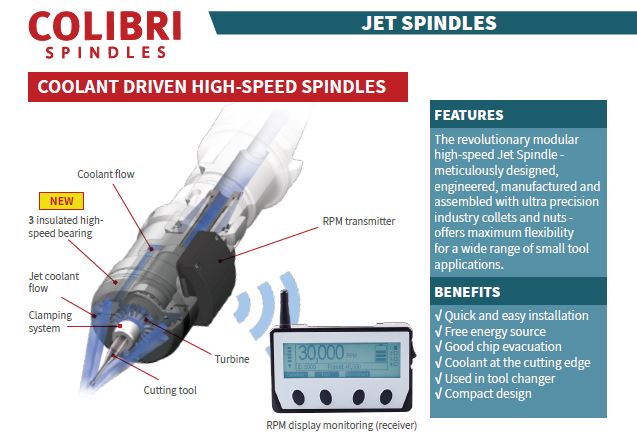

COOLANT DRIVEN HIGH-SPEED SPINDLES

In a nutshell, this is the jet spindle, how it works and what are its main features and benefits.

High-pressure coolant flows in from the back of the holder and powers the hydro turbine.

RPMs are tracked via a blue tooth connection between the jet spindle sensor and wireless display.

The jet spindles are meticulously designed, engineered, manufactured, and assembled with ultra-precision industry collects and nuts, offering maximum flexibility for a wide range of small tool applications.

BENEFITS include:

√ Quick and easy installation

√ Free energy source

√ Good chip evacuation

√ Coolant at the cutting edge

√ Used in the tool changer

√ Compact design

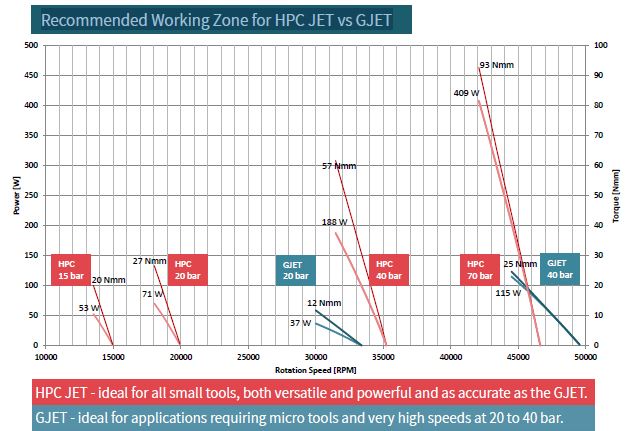

Recommended Working Zone for HPC JET vs GJET

The new chart plots the GJET and HPC Jet Spindles together,

Clearly presenting GJETs advantages in micro-milling with 20 to 40 bar of pressure; as against

The HPC’s higher torque/power and ability to work from 15 to 70 bar on the full range of small tool applications (0.1 – 6 mm cutting tool diameter).

G JET – SPEED FOR MICRO TOOLS

We are sending a very clear message to customers:

The GJET is your choice for high-speed micro milling and drilling.

The NEW Jet Spindle Operating Parameters table is packed with all the answers you will need to provide your customers:

√ High-pressure coolant and flow supported and expected RPMs and Max Torgue and Power

√ Collet provided and max runout (3 microns at the length of 3D)

√ Applications and cutting tools, recommended tool diameter range per material type (P (Steel), M (Stainless Steel), N (Nonferrous metals – aluminum, copper, lead, nickel, tin, titanium, and zinc, and alloys such as brass) and S (Superalloys – nickel, iron-nickel and cobalt alloys used in jet engines)

√ Link to the GJET online catalog to access DXF and STP files by GJET adapter – C5, C6, CAT40, SK30, SK40, ER32, ST20, HSK-A40, HSK-A63, BT30, and BT40

√ Images of the GJET in action!

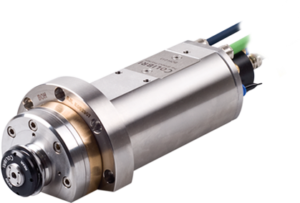

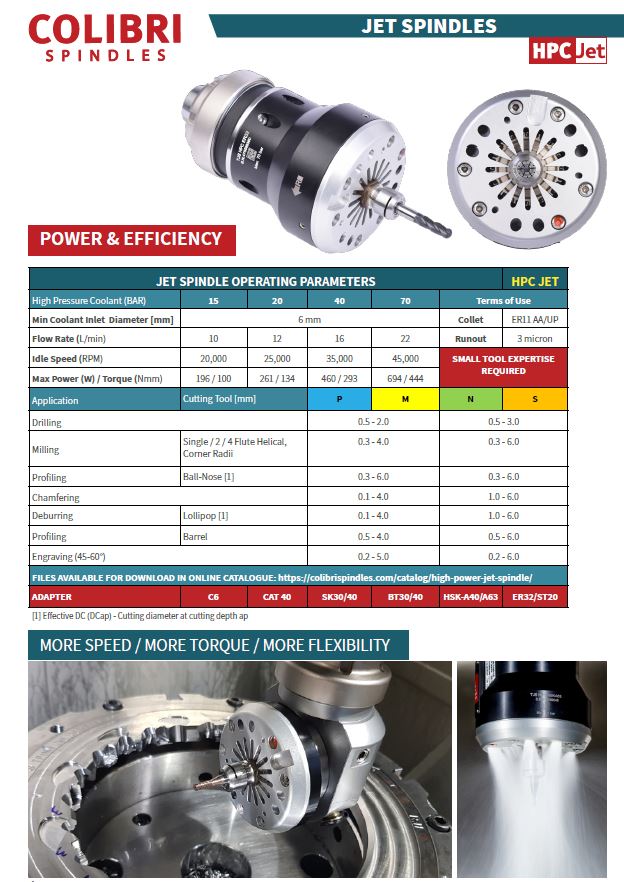

HPC JET – POWER & EFFICIENCY

The NEW Jet Spindle Operating Parameters table makes things very clear:

MORE SPEED / MORE TORQUE / MORE FLEXIBILITY

The HPC is the most versatile and powerful jet spindle we have.

Supporting the largest range of small tools and applications with the biggest range of high-pressure coolants.

The NEW Jet Spindle Operating Parameters table for HPC JET is packed with all the answers you will need for your customers:

√ High-pressure coolant and flow range (15 – 70 bar) supported and expected RPMs and Max Torgue and Power for each.

√ Collet provided and max runout (3 microns at the length of 3D)

√ Applications and cutting tools, with recommended tool diameter range per material type (P (Steel), M (Stainless Steel), N (Nonferrous metals – aluminum, copper, lead, nickel, tin, titanium, and zinc, and alloys such as brass) and S (Superalloys – nickel, iron-nickel and cobalt alloys used in jet engines)

√ Link to the HPC JET online catalog to access DXF and STP files by HPC JET adapter – C6, CAT40, SK30, SK40, ER32, ST20, HSK-A40, HSK-A63, BT30, and BT40

√ Images of the HPC JET in action!

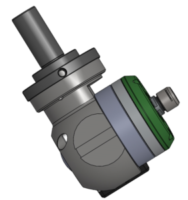

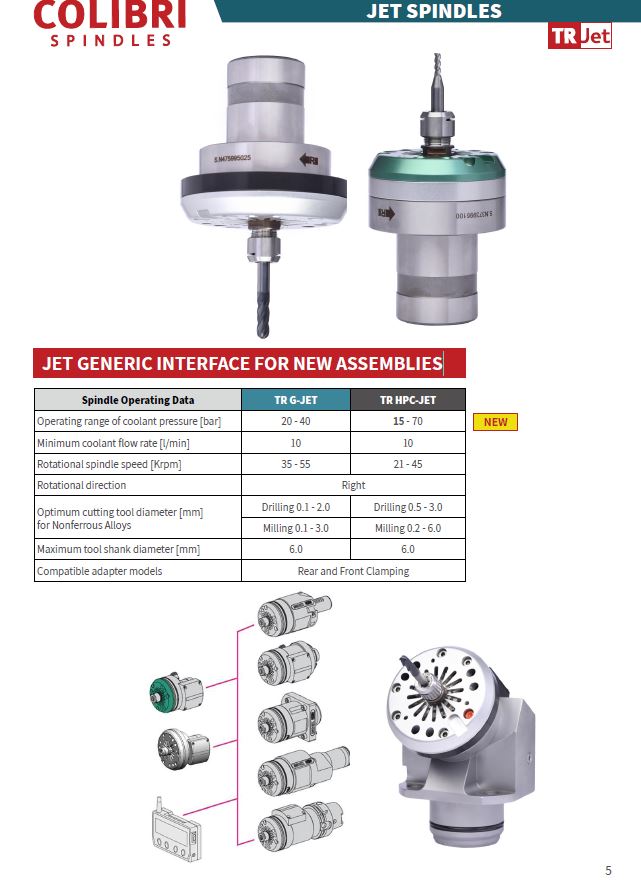

TR JET – JET GENERIC INTERFACE FOR NEW ASSEMBLIES

The TR JET is the generic interface of both the G JET & HPC JET

For holder manufacturers and MTBs

To produce custom integrated VDI and BMT holders for the HPC JET & GJET.

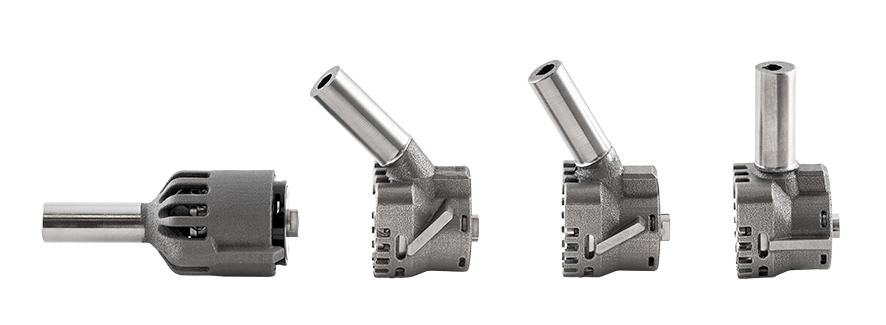

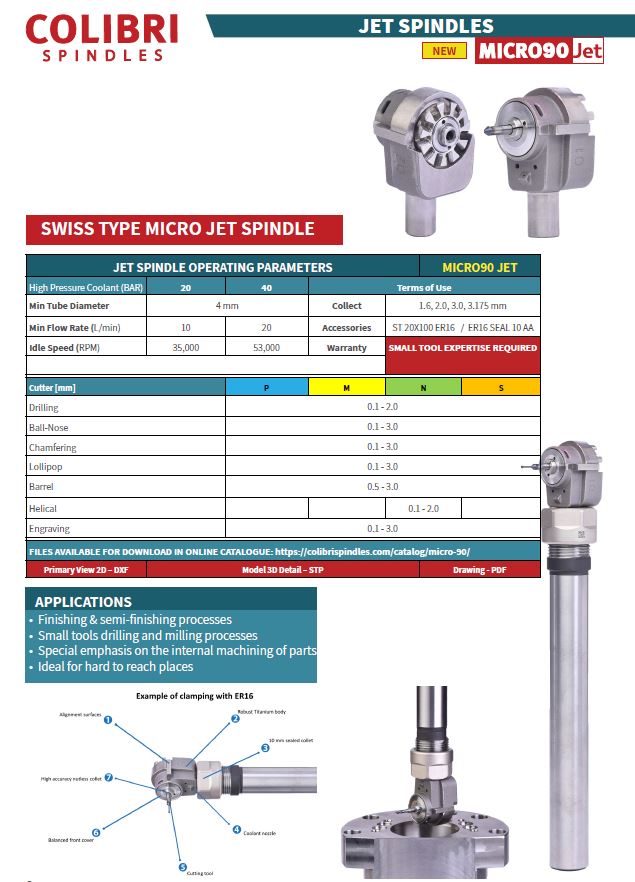

MICRO90 JET – SWISS-TYPE MICRO JET SPINDLE

The latest and hottest item in the Jet Spindle Family is the small but powerful MICRO90 Jet.

This small new 90 degrees jet spindle is ideal for milling and drilling with small tools in hard-to-reach places.

APPLICATIONS

• Finishing & semi-finishing processes

• Small tools drilling and milling processes

• Special emphasis on the internal machining of parts

• Ideal for hard to reach places

HIGH SPEED MACHINED PARTS

A picture tells a thousand words so we have included 6 pictures to

Provide your customers with 6,000 reasons why jet spindles can help them to be more competitive and profitable!

Images are of parts machined with our Jet Spindles, by product and process type.

Colibri, through its global partners, has sold thousands of jet spindles over the last several years,

so this is a small visual example of the capabilities.

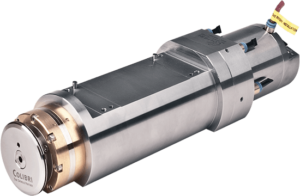

PARTNERS

Colibri is proud to be working with global leaders in metal machining.

The back page includes a very recent image of an Index Traub G220 (Turn-mill center) with a GJET TR inside an Index holder.

We have been working with Index Traub through our global partner Iscar for several years and new orders are continuing to flow in.

Please get in touch with us with your local branding and translation needs.

And keep an eye open for more NEW product and marketing literature updates in the coming months.