We are thrilled to welcome **Cactos Solutions LTDA** in Brazil as our newest certified service center for Colibri Spindles! This partnership will enhance our ability to serve our customers in South America with top-notch support and maintenance services.

- Home

- /

- Author: Lloyd Apter

BLOG

Exciting News: Cactos Solutions LTDA Joins Our Network as a Certified Service Center!

ISO 9001 Certified Company

Colibri Spindles is proud to announce the renewal of our ISO 9001:2015 certification, marking a significant milestone in our commitment to quality and customer satisfaction. In this blog post, we explore what this certification means for our company, the principles that guide our operations, and our vision for continuous improvement. Join us as we reaffirm our dedication to excellence and look forward to new opportunities ahead!

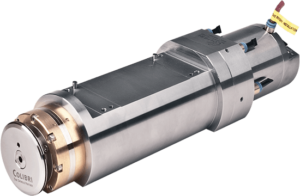

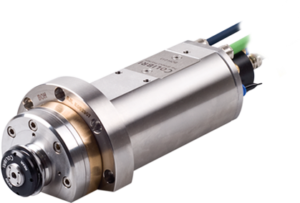

INDEX G220 GJET

The Index G220 turning, milling, and grinding center enables Haidlmair to machine precision parts for the FDU hot runner system in a single clamping. The GJET TR counter spindle provides the 3.0 mm nozzle diameter of the pre-chamber bushings is precision-ground within a tolerance range of +0.005 mm with a grinding pin (speed up to 40,000 rpm). Full translated article from xtechnik March 2022 publication. The GJET TR is referred to as the counter spindle in the article.

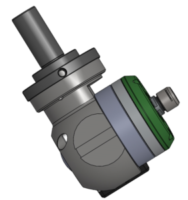

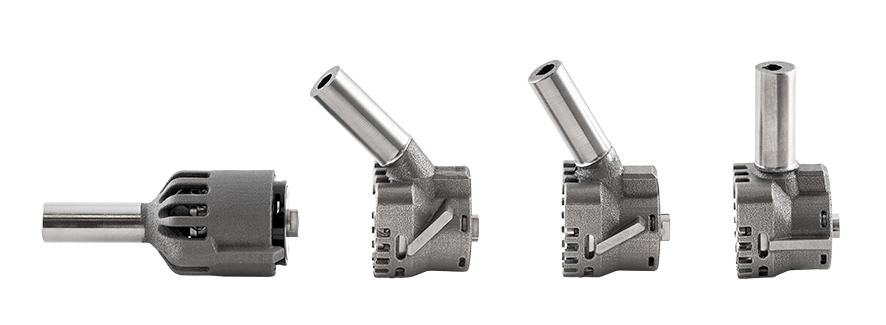

ISCAR SPINJET MICRO90 NPA

On March 13th, ISCAR released the SPINJET MICRO90 NPA with a stunning interactive announcement document. A lot of hard work has gone into this new product announcement. You will notice that the document is detailed and informative and includes detailed recommended cutting conditions, by material, application, and machine high-pressure coolant pressure.

Jet Spindle Quick Start

The Jet Spindle Quick Start is a concise document to affect Jet Spindle sales. The document is in the form of a two-sided leaflet PDF where one side provides key point points to review and the other side provides a PDF interactive form to complete, save and share with our Technical Support Team.

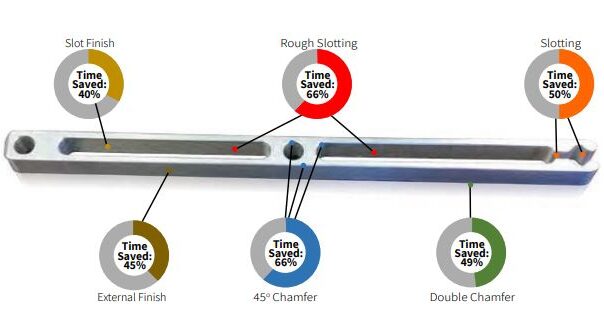

Jet Spindle Application Insights: Slot Milling

SPINJET Case Studies – ISCAR Slovakia covers two case studies completed at the same Customer, LOMAN. The first article focused on the case study involving the chamfering of an aluminum plate and this second article focuses on the case study covering the slot milling of stainless steel. Both with the GJET.

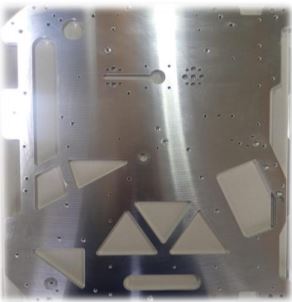

Jet Spindle Application Insights: Chamfering

SPINJET Case Studies – ISCAR Slovakia covers two case studies covered at the same Customer, LOMAN. The first case study focused on aluminium plate chamfering and the second case study focuses on stainless steel slotting. Both with the GJET.

Jet Spindle Application Insights: Engraving

Engraving is an ideal application for jet spindles and process time savings of 6-12X can be achieved, which is the equivalent of saving 80-98% saving in machining time!

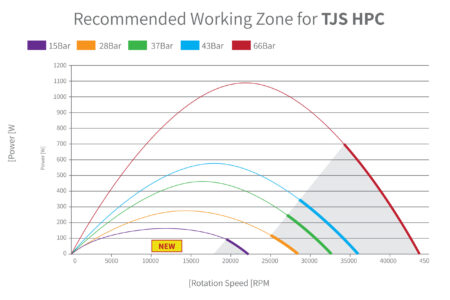

NEW JET Spindle Operating Parameters

We have updated our Jet Spindle Operating Parameters tables to provide more information. We now include information connecting high-pressure coolant pressure and flow to unit torque. We provide a list of cutting tools and sizes for different material grade categories. We relate to collect size and type, runout, and warranty.

BIG Opportunities – SMALL Tools

Operationally, once the roughing processes are completed on large machines, we need to physically move the rough part to machines that are better equipped to complete the finishing processes efficiently and accurately. This implies a string of additional activities and costs, including additional costly high-speed machines, planning, and machine setup. Ideally, we want to complete all the processing efficiently and accurately on the same large machine and in the same setup. This is much more profitable.

Latest News

-

29

Oct -

13

OctBlog post ISO 9001 Certified Company -

09

JulBlog post Jet Spindles Industry Guide – Medical -

09

MayBlog post Jet Spindle Certified Service Centers -

16

FebBlog post WHAT’S NEW at TAEGUTEC? !