This new comprehensive guide provides Colibri Jet Partners with a valuable document to guide their sales personnel through the Jet Spindle sales process.

The guide supports the salesperson in identifying the correct Jet Spindle for the Customers’ application by covering all the possibilities and options that need to be addressed in determining the best Jet Spindle product type and operating parameters for the job.

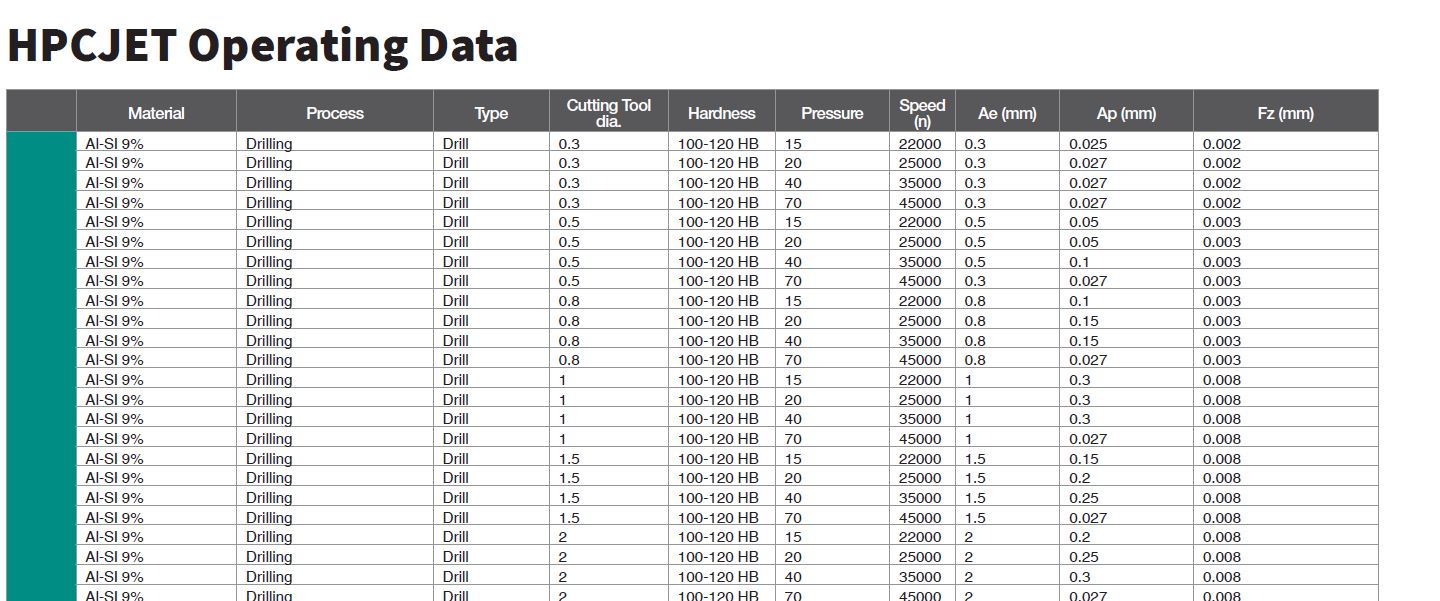

The guide continues to support the salesperson through the demo and first-time setup for each Jet Spindle, explaining, in detail, how to use each Jet Spindle product for the full range of milling and drilling applications providing the Speed (n), Ae (mm), Ap (mm) and Fz (mm) values based upon material type and its hardness, coolant pressure, process, cutting tool type, and cutting tool dimensions.

This blog post will provide you with an overview of the new Jet Spindles Presale and Quick Start Guide, explaining its contents and how best to use it.

You can download the guide with this link: Jet Spindles Presale and Quick Start Guide

Jet Spindles Presale Guide

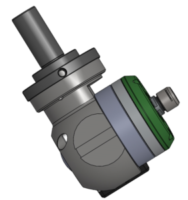

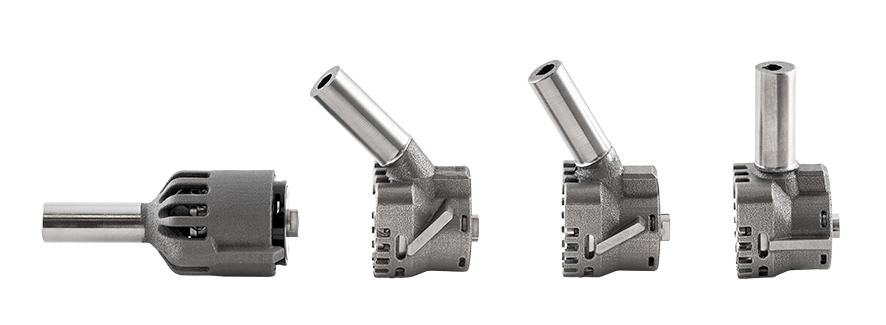

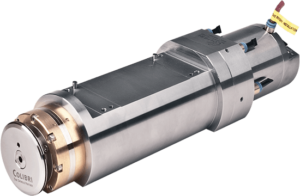

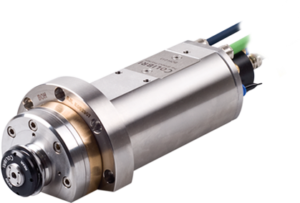

The guide is divided into two sections. The first section covers the presale process which entails identifying the correct jet spindle for each appropriate customer application, while the second part focuses on the technicalities of setting up and beginning to work with each jet spindle product type, namely HPCJET, GJET, and MICRO90 JET.

An overview of the presale guide section is well covered in our previous blog post so please read this blog post to best acquaint yourself with the jet spindle product family before continuing with the rest of this post:

Jet Spindles Quick Start Guide

The new quick start guide has grown from just 2 pages to a 12-page document, jam-packed with all the important details to set up and test the Jet Spindle on the full scope of Customer applications.

We realize that this is a lot of information and we will be announcing later this month training webinars on how to use this guide effectively.

What is important is that sales personnel now have the information at their fingertips to take a potential Customer from presale to setup / first application to sales!

Jet Spindle Setup

Most experienced Jet Spindle Partners will recognize this as the existing Quick Start Guide, which it is.

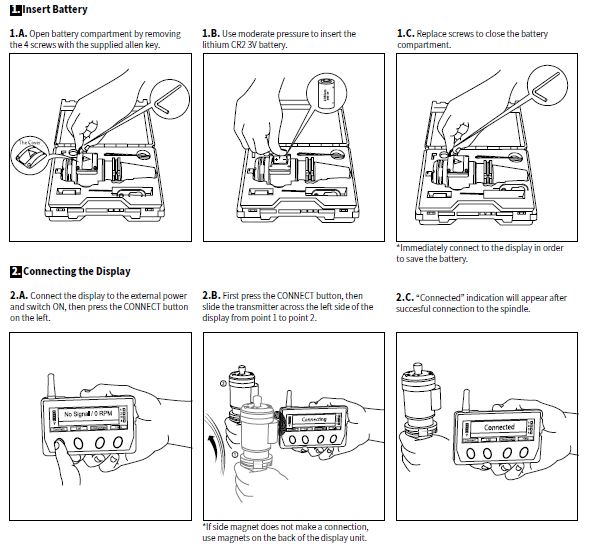

The section covers setting up the sensor and the Jet Display and connecting them. It is important to point out that to connect the unit with the display it is critical to first insert a CR2 3V battery in the Jet Spindle plastic sensor housing; plug the Jet Display into an electrical outlet and then, after switching the Jet Display ON, play the plastic sensor housing against the antenna side of the Jet Display. “Connected” indication will appear after a successful connection to the Jet Spindle.

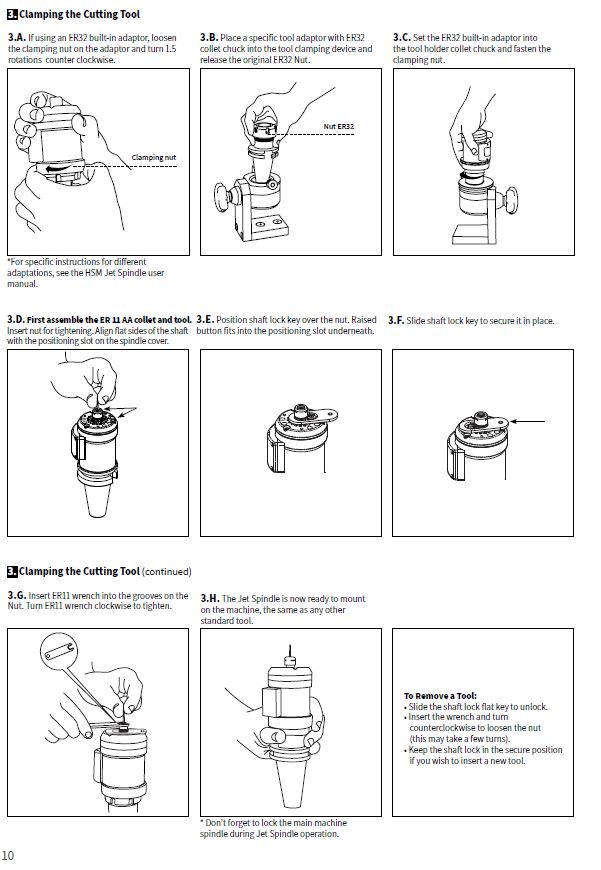

Clamping the Cutting Tool

Important Unclamping tip:

How to correctly open the nut during unclamping cutting tools with ER11 MS Nut?

When unclamping make sure to turn the wrench several revolutions anti-clockwise to ensure that the ER11 MS Nut and ER11 AA Collet are both properly loosened.

If you turn the wrench around only 1-2 revolutions anti-clockwise when unclamping the ER11 MS Nut the ER11 AA Collet will not be loosened and will remain stuck in the cone.

Please watch the short video on YouTube below.

The first part of the video shows what not to do (marked with an ![]() ), which is then followed by the second half which demonstrates the correct (marked with an

), which is then followed by the second half which demonstrates the correct (marked with an![]() ) process.

) process.

Milling & Dilling with Jet Spindles

Pages 11 and 12 include totally new information for our partners and are very important for selling to and supporting Jet Spindles Customers.

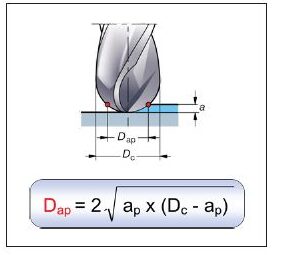

These two pages cover the 5 most important formulas and rules of thumb for effectively and safely working with Jet Spindles, including:

- Slot Milling Formula

- Profile Milling Formula

- Drilling Formula

- 10% Speed Drop Rule

- 30% Feed Rate Rule

Please let us know if you have any questions regarding these formulas and rules of thumb.

Jet Spindle Operating Data

Half of the document is devoted to providing our Jet Partners with specific operating data by the Jet Spindle product line.

Based on material type and its hardness, coolant pressure, process, cutting tool type and cutting tool dimensions the tables provide Speed (n), Ae (mm), Ap (mm) and Fz (mm) values.

You can download the guide with this link: Jet Spindles Presale and Quick Start Guide

Any questions? Contact us.