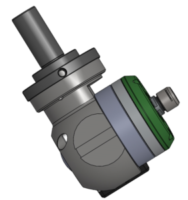

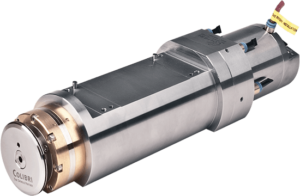

Colibri Spindles line of Jet Spindle Speeders

When we look at high-speed machining we are looking at the machine’s spindle revolutions per minute of a maximum of 25,000 to 42,000 RPMs.

The need for higher machine spindle RPMs when using smaller tools is not a new issue in the machining world. To machine effectively, small tools must rotate faster than larger tools, removing less material per tooth.

For over 40 years the machining industry has been developing solutions to solve the challenge to increase the machine spindle speed during processing from the relatively low machine spindle RPMS which are required for larger tools to speeds of 3-5 times faster.

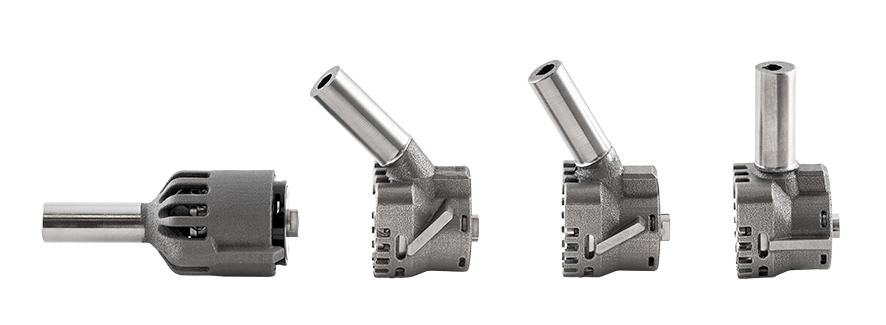

Spindle speeders is the term used for a device that is attached to the end of the machine spindle to increase the RPMs of the machine spindle. Initial all spindle speeders with mechanical, using gears to accelerate the machine spindle. Thus the name spindle speeder made was coined. However, in more recent years alternative solutions have been developed that neutralize the machine spindle and so are not really spindle speeder or speed increases but are rather a micro spindle that replaces the machine spindle when operated.

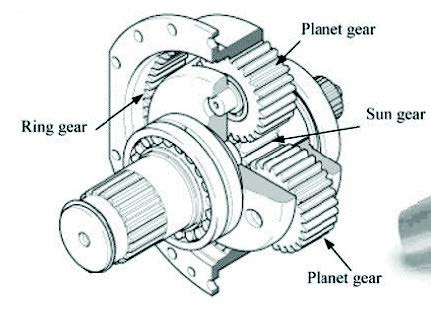

MECHANICAL SPINDLE SPEEDERS

Traditionally machine spindles were geared up to increase the spindles RPMs for working with small tools. This was and still is done by adding a spindle speeder device with mechanical gears but this solution has many issues, notable amongst the issues are the heating up and over usage of the machine spindle as well as the lack of precision machining at high RPMs.

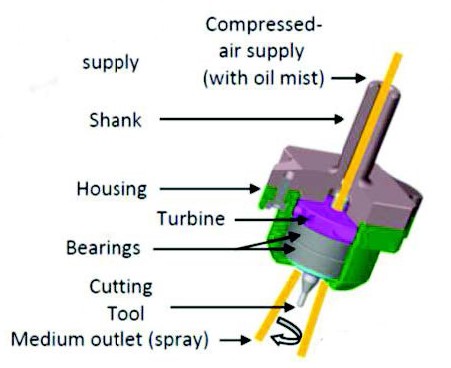

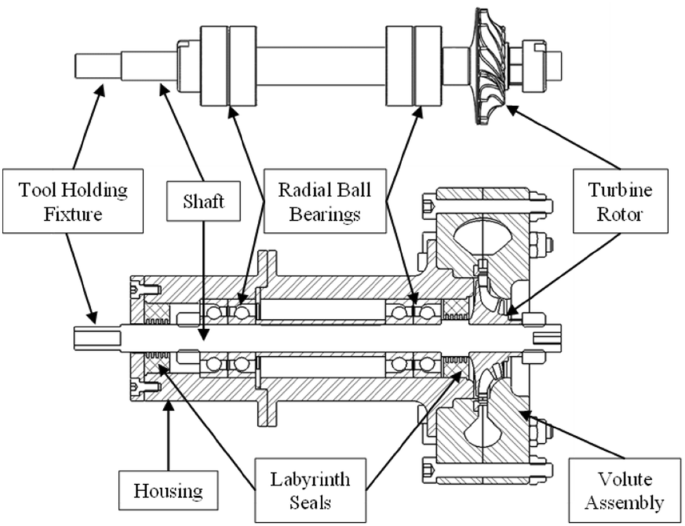

AIR TURBINE SPINDLE SPEEDERS

Turbine or air spindle speeders use compressed air as an energy source and therefore require retrofitting the CNC machine with compressed air. The compressed air is of course limited to each machine and adds to the running cost of each machine. Compressed air, by nature, also provides limited power by its nature, which can be an issue when completing more challenging tasks of the machine spindle and lack of precision at high RPMs.

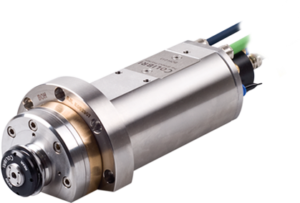

MOTOR SPINDLE SPEEDERS

The third traditional spindle speeder technology uses an electrical motor for power, requiring each machine to be specially retrofitted with an electrical power source. This electrically powered spindle speeder involves greater investment and running costs and is complex to work with as the spindle speeder much be connected to an electrical power cable throughout the machining process.

COLIBRI SPINDLES

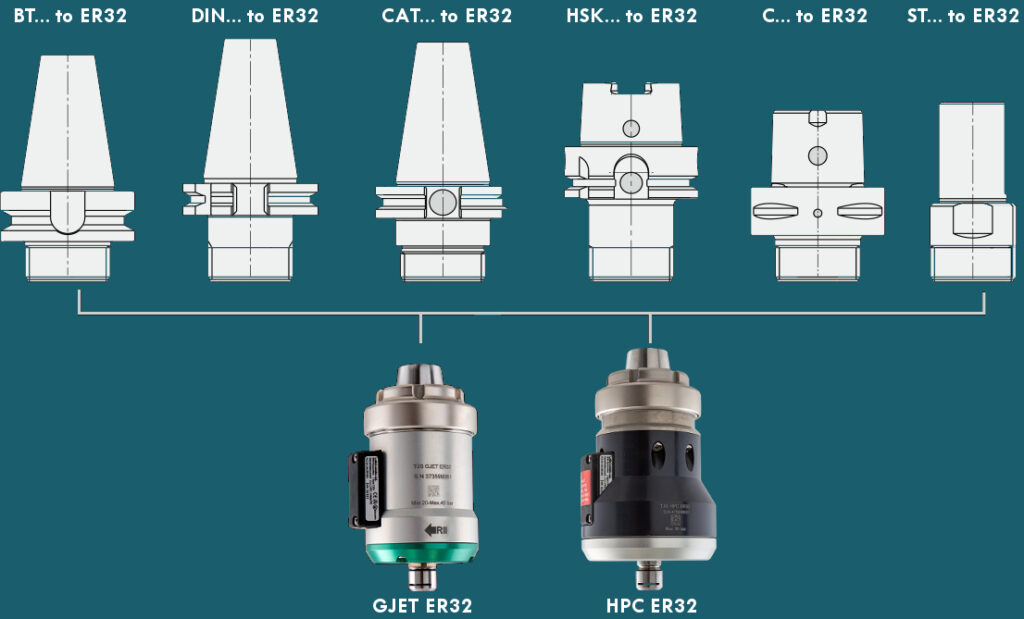

Colibri Spindles, a world leader in high-speed spindles as developed a totally unique solution that uses the CNC machines high-pressure coolant to power its range of Jet Spindle Speeders. Colibri Jet Spindle Speeders offer extremely low run out of 1 micron on the cone, require zero investment in retrofitting the machine, and zero additional operating costs.

JET SPINDLE SPEEDERS

The Colibri Jet Spindle Speeders are used throughout the world in demanding environments – from world leading cutting tool production to aerospace part manufacturing – requiring the fast processing of harden metals with extreme precision 24/7, non-stop.

Colibri Jet Spindle Speeders are powered by the machine’s own high-pressure coolant (HPC), optimize processing with small tools.

Zero machine upgrade investment plus Zero energy consumption add towards making Colibri Jet Spindle Speeders the most efficient and cost effective Spindle Speeders on the market!

Colibri Jet Spindles, a patented technological breakthrough, have totally revolutionized the market for spindle speeders. These Jet Spindle Speeders are easy to use, rugged yet high accurate, and powerful.