We recommend checking and cleaning the coolant nozzles every three months or when you experience a sudden decrease in the performance of the jet spindle. From our experience, small cut metal chips can find their way through the jet cover into the area of the turbine and high-pressure coolant nozzles. This article will take you through the step-by-step process of cleaning the coolant nozzles. If you have any questions please contact our technical support team. All that you need is a 4T Allen key and Loctite #222 adhesive.

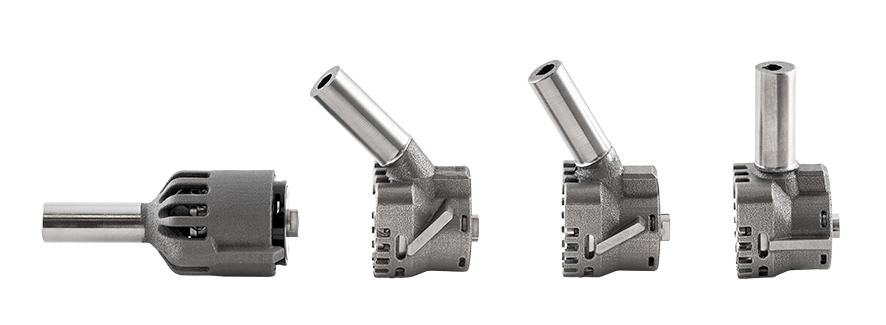

1. Removing Front Cover

Loosen the 3 front cover screws using a 4T Allen key.

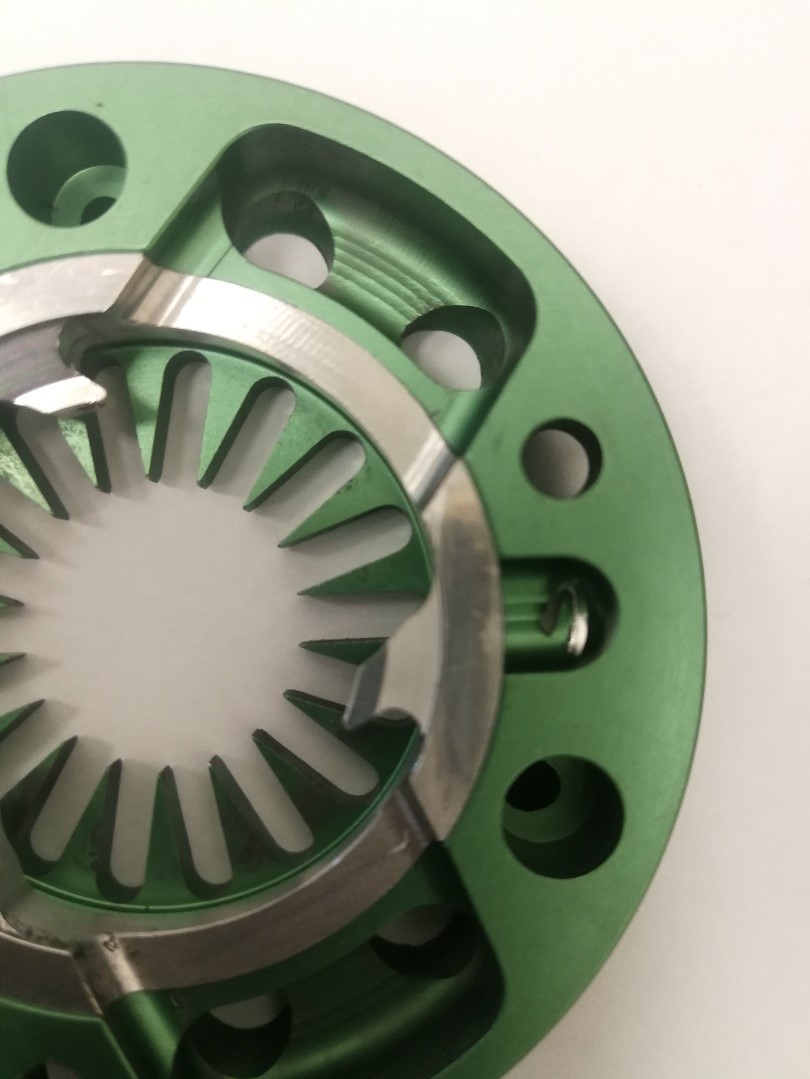

2. Check the Sealing Gasket

Remove the cover and make sure that the sealing gasket is in good shape and remains in position.

NB If the sealing gasket is damaged you can order a new one.

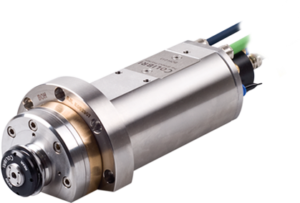

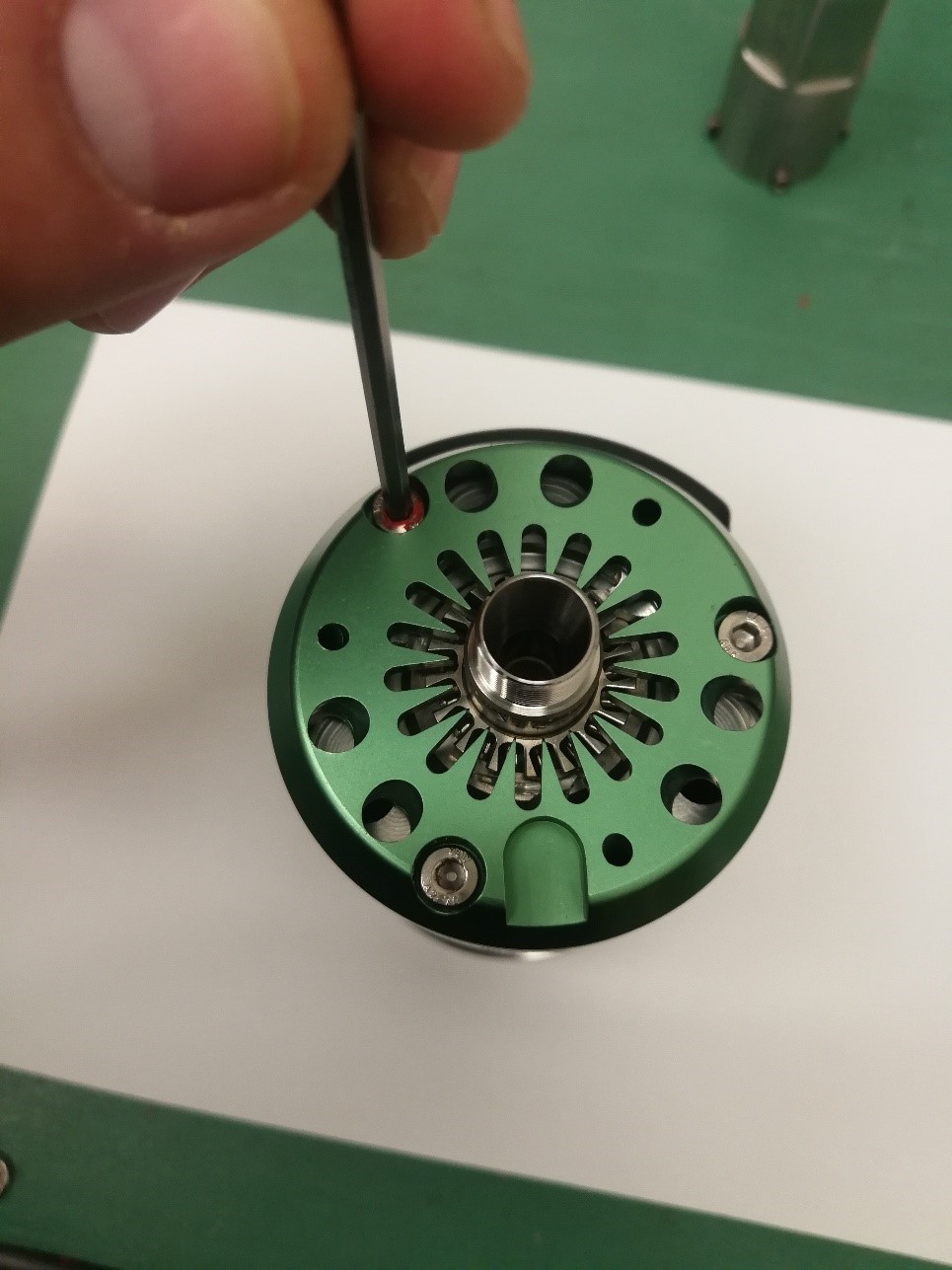

3. Cleaning the Coolant Nozzles

Assure that the coolant nozzles are free of debris.

Use a metal wire and compressed air to remove any cutting chips or dirt,

that possibly block the nozzle holes and interrupt the flow.

4. Re-assembling Front Cover

Again ensure the sealing gasket is in place.

Place the front cover on the assembled unit and tighten the screws using a 4T Allen key.

Use Loctite #222 to secure the screws.