We have updated our Jet Spindle Operating Parameters tables to provide more useful information. We now include data connecting high-pressure coolant pressure and flow to unit torque. We provide a list of cutting tools and sizes for different material grade categories. We relate to collect size and type, runout, and provide warrant information.

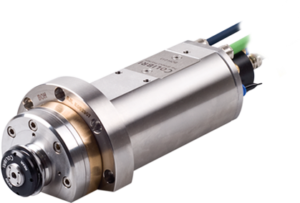

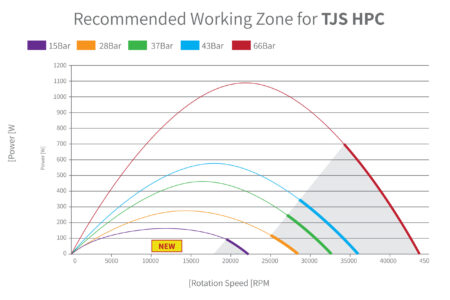

Let’s take a look at the new HPC Jet table.

HPC JET Spindle Operating Parameters

| JET SPINDLE OPERATING PARAMETERS | TJS HPC | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| COOLANT | 15 BAR | 20 BAR | 40 BAR | 70 BAR | Terms of Use | ||||||

| Supply Diameter | 4 mm | Collet | ER11 AA/UP | ||||||||

| Flow Rate | 10 L/min | 12 L/min | 16 L/min | 22 L/min | Runout | 3 micron | |||||

| Speed | 20,000 RPM | 25,000 RPM | 35,000 RPM | 45,000 RPM | Warranty | 1 Year | |||||

| Torque | 0.02 Nm | 0.03 Nm | 0.06 Nm | 0.09 Nm | SMALL TOOL EXPERTISE REQUIRED | ||||||

| Cutter [mm] | P | M | N | S | |||||||

| Drilling | 0.1 – 2.0 | 0.1 – 2.0 | 0.1 – 3.0 | 0.1 – 2.0 | |||||||

| Single / 2 / 4 Flute Helical, Corner Radii | 0.1 – 4.0 | ||||||||||

| Ball-Nose [1] | 0.1 – 3.0 | ||||||||||

| Chamfering [1] | 0.1 – 4.0 | ||||||||||

| Lollipop [1] | 0.1 – 6.0 | ||||||||||

| Barrel | 0.5 – 4.0 | ||||||||||

| PCD Tipped | 0.1 – 3.0 | ||||||||||

| Engraving [1] | 0.2 – 6.0 | ||||||||||

| ER32/ST20 | BT30/40/50 | HSK-A63/A40 | SK30/40 | CAT 40/50 | C5/6 | ||||||

| [1] Effective DC (DCap) – Cutting diameter at cutting depth ap | |||||||||||

- Coolant pressure is measured from the spindle inlet

- Rotational spindle speed is based on coolant pressure and flow rate

- Spindle speed may vary up to 7%

HPC JET Operating Parameter Notes

Some important points to note. HPC Jet can be operated from 15 bar high-pressure coolant. This is possible because of its larger turbine.

Furthermore, still, on the subject of high-pressure coolant, the HPC Jet can operate 70 bar as well. Giving this Model the maximum versatility in terms of the range of high-pressure coolant.

As a standard, the HPC Jet uses an ER11 high-precision collect and can guarantee a runout of a maximum of 3 microns.

When we look at the section focusing on the types of cutters by material type and size, it’s clear that the HPC Jet can handle the work of medium to small-sized tools. Again, giving the HPC Jet the upper hand in terms of versatility of use.

You can access specific and detailed information regarding the use of HPC JET with different cutting tool diameters in our HPC JET Operating Conditions for Shoulder and Slote Milling datasheet.

Let’s have a look now at the NEW operating parameters table for the GJET Spindle.

GJET Spindle Operating Parameters

| JET SPINDLE OPERATING PARAMETERS | TJS GJET | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| COOLANT | 20 BAR | 40 BAR | Terms of Use | ||||||

| Min Supply Diameter | 2 mm | Collet | ER11 | AA/UP | |||||

| Min flow rate | 10 L/min | 20 L/min | Runout | 3 micron |

At length of 3D |

||||

| Speed | 33,000 RPM | 55,000 RPM | Warranty | 1 Year |

Standard | ||||

| Torque | 0.05 Nm | 0.09 Nm | SMALL TOOL EXPERTISE REQUIRED | ||||||

| Cutter [mm] | P | M | N | S | |||||

| Drilling | 0.1 – 2.0 | 0.1 – 2.0 | 0.1 – 3.0 | 0.1 – 2.0 | |||||

| Single / 2 / 4 Flute Helical, Corner Radii | 0.1 – 3.0 | ||||||||

| Ball-Nose [1] | 0.1 – 3.0 | ||||||||

| Chamfering [1] | 0.1 – 4.0 | ||||||||

| Lollipop [1] | 0.1 – 6.0 | ||||||||

| Barrel | 0.5 – 3.0 | ||||||||

| PCD Tipped | 0.1 – 3.0 | ||||||||

| Engraving [1] | 0.2 – 6.0 | ||||||||

| ADAPTER | ER32/ST20 | BT30/40/50 | HSK-A63/A40 | SK30/40 | CAT 40 | C5/6 | |||

| [1] Effective DC (DCap) – Cutting diameter at cutting depth ap | |||||||||

- Coolant pressure is measured from the spindle inlet

- Rotational spindle speed is based on coolant pressure and flow rate

- Spindle speed may vary up to 7%

GJET Operating Parameter Notes

As we can see when comparing the HPC Jet to the GJET Spindle, the GJET has the upper hand when it comes to speed.

If speed is what we are looking for and therefore we are working only with small diameter tools, the GJET is what we need.

Like the HPC Jet, the GJET offers excellent versatility for milling with small tools.

You can access specific and detailed information regarding the use of GJET with different cutting tool diameters in our GJET Operating Conditions for Shoulder and Slote Milling datasheet.

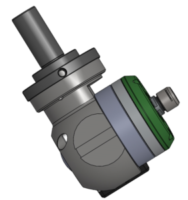

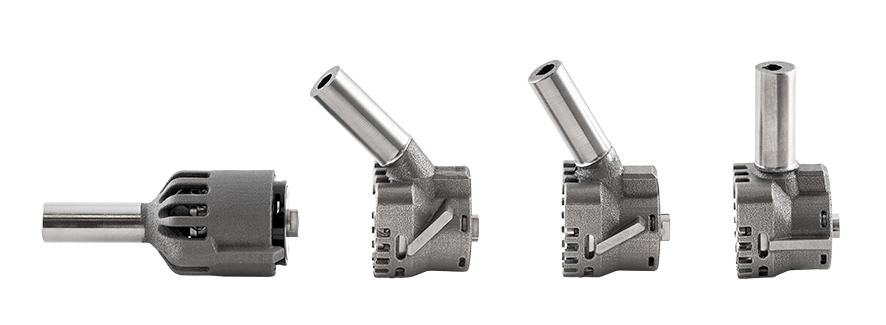

Lastly, let’s look at the latest addition to the Jet Spindle family – the MICRO90.

MICRO90 JET Spindle Operating Parameters

| JET SPINDLE OPERATING PARAMETERS | MICRO90 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| COOLANT | 20 BAR | 40 BAR | Terms of Use | ||||||||

| Min Supply Diameter | 4 mm | Collet | CHS | ||||||||

| Min flow rate | 10 L/min | 20 L/min | Runout | 3 microns at the length of 3D | |||||||

| Speed | 35,000 RPM | 45,000 RPM | Warranty | 1 Year Standard | |||||||

| Cutter [mm] | P | M | N | S | |||||||

| Drilling | 0.1 – 2.0 | ||||||||||

| Ball-Nose [1] | 0.1 – 3.0 | ||||||||||

| Chamfering [1] | 0.1 – 3.0 | ||||||||||

| Lollipop [1] | 0.1 – 3.0 | ||||||||||

| Barrel | 0.5 – 3.0 | ||||||||||

| Helical | 0.1 – 2.0 | ||||||||||

| Engraving [1] | 0.1 – 3.0 | ||||||||||

| [1] Effective DC (DCap) – Cutting diameter at cutting depth ap | |||||||||||

- Coolant pressure is measured from the spindle inlet

- Rotational spindle speed is based on coolant pressure and flow rate

- Spindle speed may vary up to 7%

MICRO90 JET Operating Parameter Notes

The MICRO90 is small but rugged and very fast!

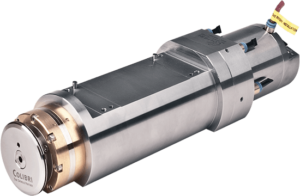

Printed from titanium powder and engineered to precision at Colibri Spindles, this unit is used in our production of dicing spindles, where accessing difficult to reach places is a big challenge.

Perfect for drilling and milling in very narrow and hard-to-reach places, this new SWISS Type Jet Spindle is a great addition to any machining operation.

We hope you find the new information useful.

If you have any special needs please feel free to reach out to one of the technical experts for assistance or just contact us for assistance.