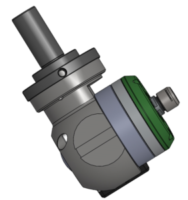

MICRO90 Jet Spindle Speeder

SMALL & FAST!

IDEAL TOOL FOR DRILLING IN DIFFICULT TO REACH PLACES.

Offering speeds from 35,000 to 45,000 rpm while the main machine spindle remains idle.

The Micro90 Jet Spindle Speeder is ideal for a wide range of semi-finishing and finishing applications using small cutting tools such as milling, drilling, thread-milling, engraving, chamfering and deburring.

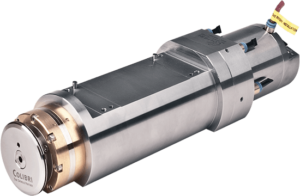

Colibri Spindles is the world leader in HPC driven spindles and one of the few global producers of high precision Semiconductor spindles. Colibri developed the range of powerful Jet Spindle Speeders as an internal development initiative to find practical solutions to high speed machining needs in its production facility in Israel. Colibri Jets use Industry 4.0 technology to provide real-time display monitoring of performance.

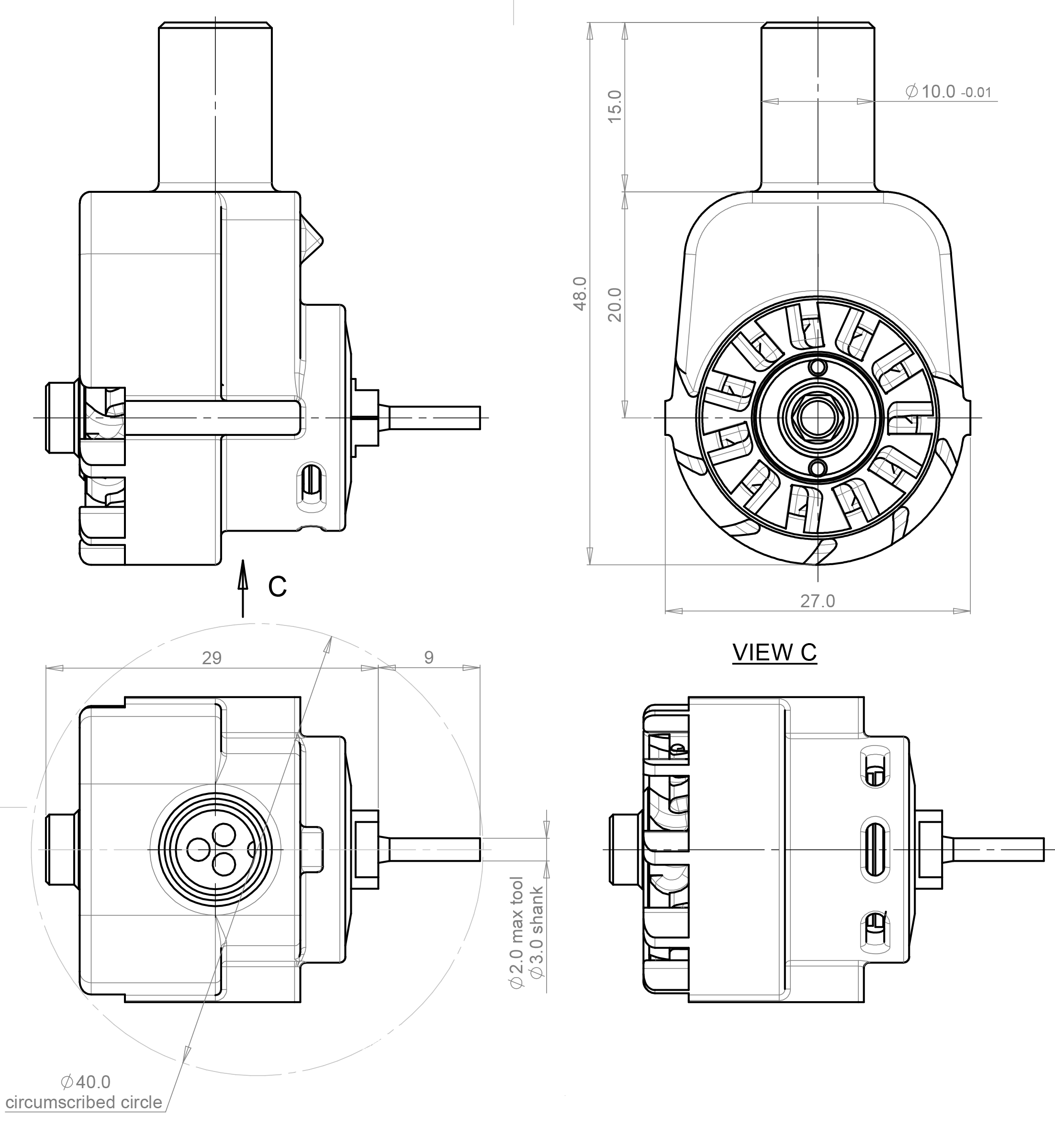

The MICRO 90 Jet Spindle Speeder, with a solid shell of titanium and assembled from only six parts is build for powerful, accurate work in small and difficult to reach spaces. Offering speeds from 35,000 to 45,000 rpm while the main machine spindle remains idle. Ideal for a wide range of semi-finishing and finishing applications using small cutting tools such as milling, drilling, thread-milling, engraving, chamfering and deburring.

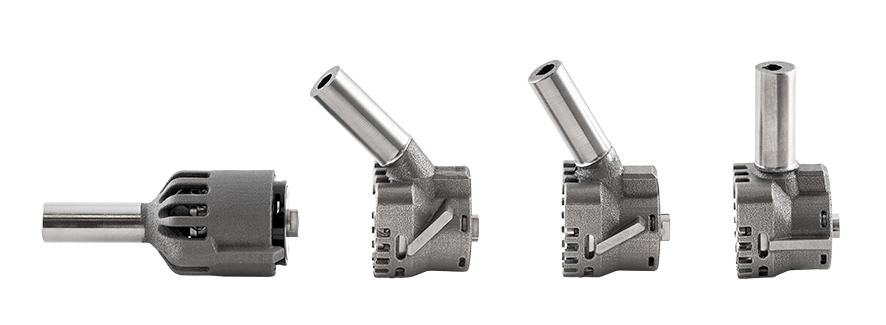

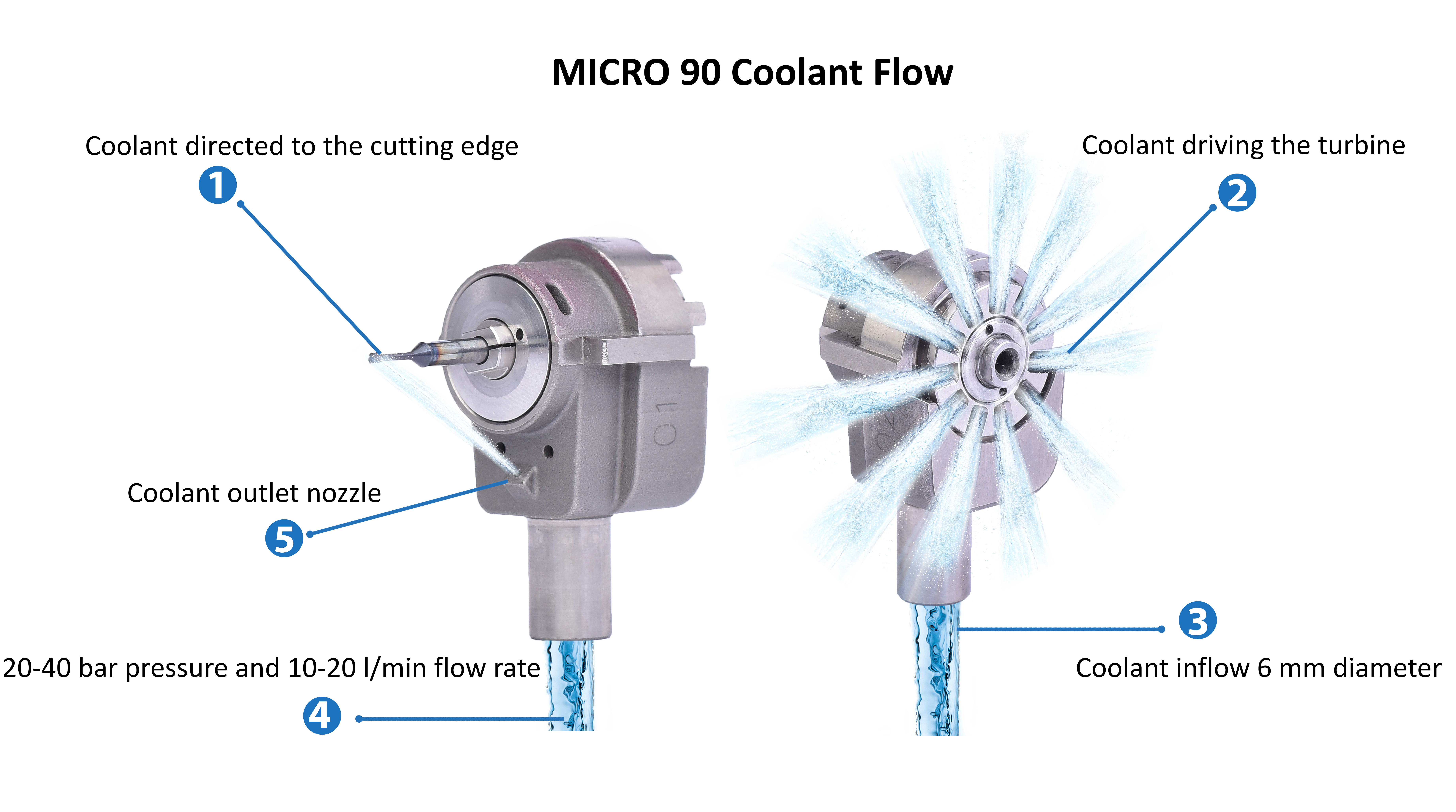

CLAMPING & COOLANT

High-speed clamping includes simplified “nutless” collet improves dynamic balancing with pointed flow towards the cutting edge. One

minute simple tool change with no setup, with minimum runout.

CHS (Nakanishi) collet type.

COOLANT OUTLETS from the turbine outlet and pointed nozzle towards the cutting edge.

FEATURES

The Micro90 Jet Spindle Speeder product range supports milling and turning machines, with the biggest advantages found in (1) turning machines because

of the massive speed increase and conversion of static holders to live holders; (2) angular holders because of simple and cheap production of angle holders as they do not require gears; and (3) smaller machines where optimizing space is a prerogative.

All Colibri Spindle Micro Jet Spindle Speeder products have identical integration options and dimensions allowing for efficient management of inventory and service.

APPLICATION LIMITS

MILLING

|

THREAD MILLING

|

DRILLING

|

GRINDING

|

DEBURRING

|

ENGRAVING

|

OPERATIONAL DATA

Spindle Operating Data |

MICRO 90 |

|---|---|

| Operating range of coolant pressure [bar] | 20 – 40 |

| Operating range of coolant flow rate [l/min] | 10 – 20 |

| Rotational spindle speed [Krpm] | 35 – 55 |

| Optimum drilling cutting tool diameter [mm] | 0.3 – 2.0 |

| Optimum milling cutting tool diameter [mm] | 0.3 – 2.0 |

| Max Output power [Watt] | 50 |

| Maximum tool shank diameter [mm] | 3.175 |

SUMMARY AND NEXT STEPS

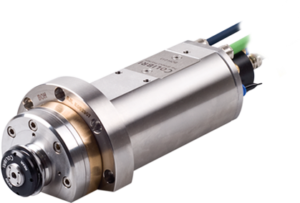

Colibri Spindles, a global leader in high precision spindles, now offers HSM Micro 90 Jet Spindle Speeders, with a simple generic interface for easy integration with machine holders.

Colibri Micro90 Jet Spindle Speeders are powered by the machines high pressure coolant and come with an CHS tool interface that can drive tools of up to 2 mm at rotation speeds of above 55,000 RPM. The use of machines coolant to drive the spindle provides a non-stop high speed machining option. The Micro design ensures easy and fast removal for maintenance. The Micro HSM Jet Spindle Speeders are ideal for turning and milling holders in limited space Swiss-Type machines.

If you are an end user looking for a solution, feel free to contact us and we will connect you with one of Our Partners.

If you are a MTB and would like to learn more about our Jet product range and partner with us contact us, for more details.