Feed Calculation Guide

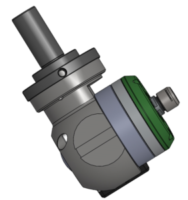

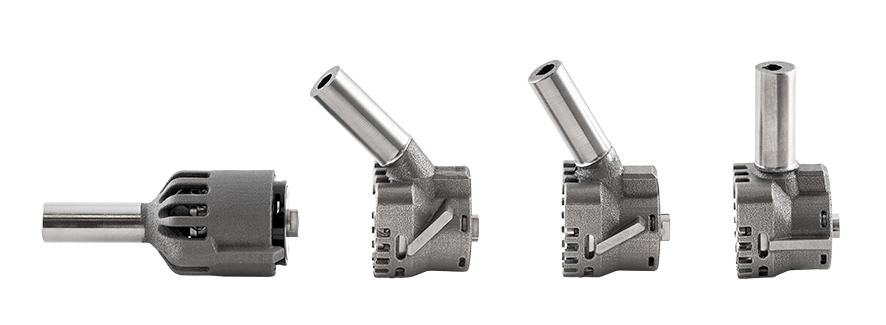

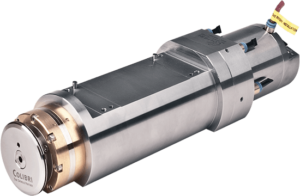

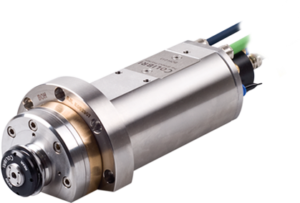

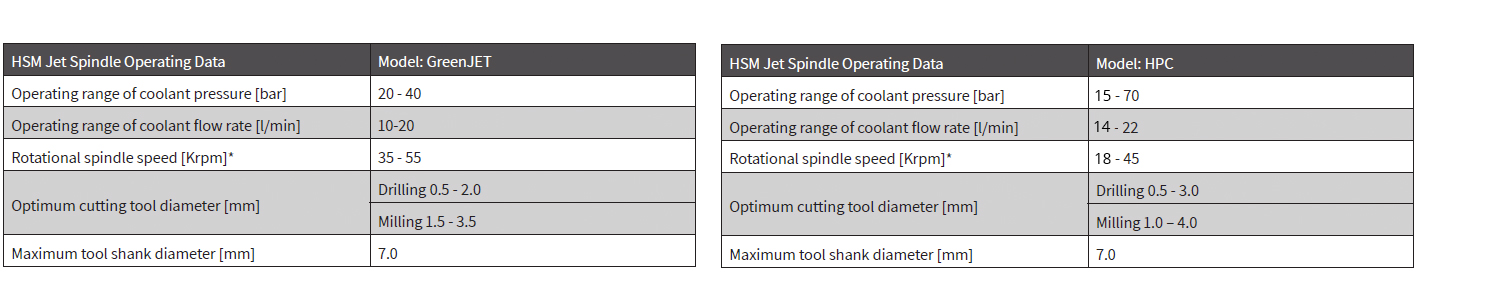

The HSM Jet Spindle system was developed to create machining conditions that enable optimal cutting speed conditions for small diameter solid carbide tools requiring high RPMs. The Jet Spindle rotates at its rated speed when idle. As the cutting tool enters the workpiece, the rotational speed may be minimally reduced. Rotational speed of the Jet Spindle (GreenJET and HPC models), is dependent upon coolant parameters and flow rate. Cutting tool parameters should be adjusted according to the rotational speed required for the desired application.

Notes:

- Rotational spindle speed is based on coolant pressure and flow rate

- Coolant pressure is measured from the spindle inlet

- It is recommended to select the smallest tool diameter, according to the application requirements

- It is recommended to select cutting tools in grades that are suitable for high speed machining

Recalculating Table Feed for HSM Jet Spindles

There are two methods of calculating table feed, F [mm/min], for operations with the HSM Jet Spindle:

- Existing machining process (transition from machining with a machine spindle to an HSM Jet Spindle)

- Selecting a new machining process

Existing Machining Process

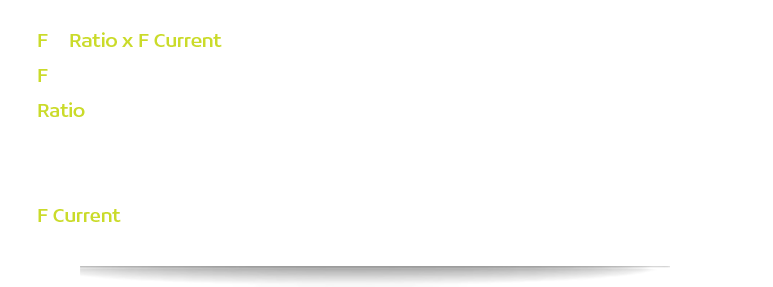

The feed per tooth fz remains constant while the table feed F increases in proportion to the HSM Jet Spindle rotation speed.

The feed per tooth fz should remain constant while the table feed F is changed.

Calculate the table feed F [mm/min], according to the following formula:

For example

If using a machine spindle at 8,000 rpm, with a table feed of 160 [mm/min], and the HSM Jet Spindle set to 30,000 rpm, then the new recommended table feed is as follows:

New table feed = 30,000/8,000 x 160 = 3.75 x 160 = 600 [mm/min].

The new table feed is 600 mm/min

3. New Machining Process

Calculate the table speed, F [mm/min], according to the formula:

F = n x z x fz

Rotation speed – n [rpm] rotation speed for table speed calculation, can be determined only after reading the actual rotation speed obtained when the tool has engaged the material.

Number of teeth – z.

Feed per tooth – fz [mm/tooth], select according to tool vendor’s recommendations, taking into consideration the machining material, application and the tool geometry.

Note:

First trial for both machining processes: It is recommended to increase the table feed gradually.