High Efficiency Machining

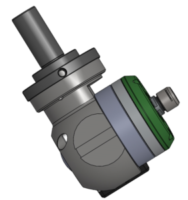

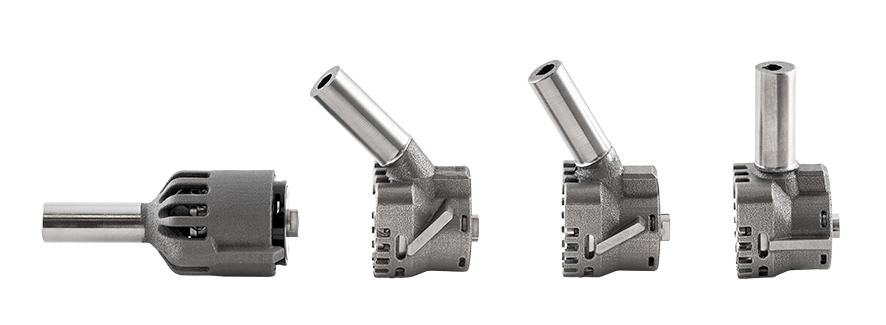

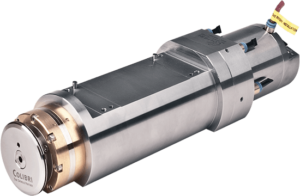

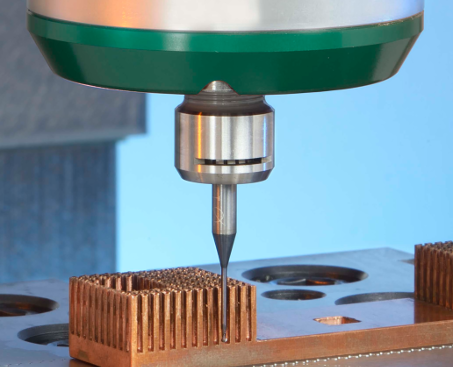

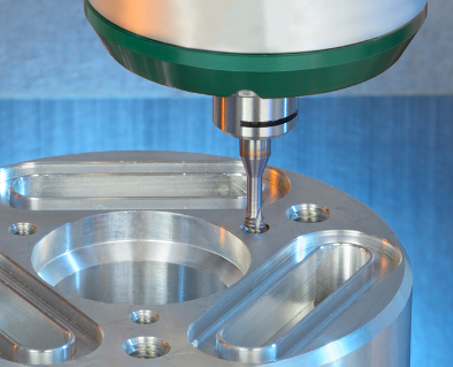

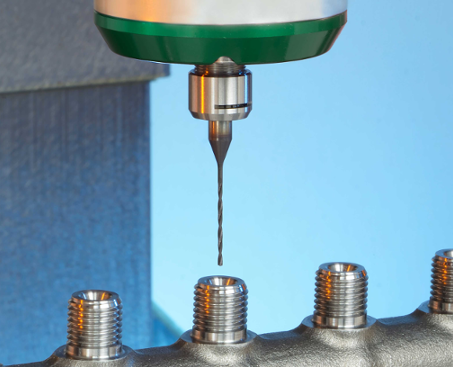

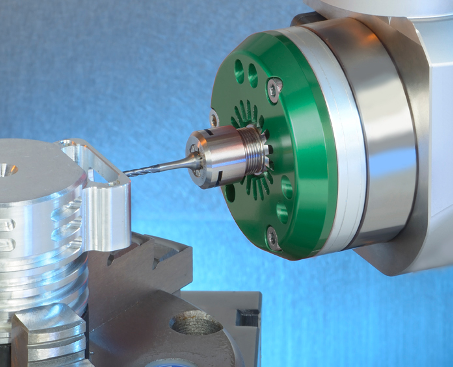

The HSM Jet Spindle enables a wide range of semi-finishing and finishing machining applications for a variety of materials. Our current product line supports cutting tools with tool shank diameters of up to 7.0 mm. Colibri is continuously engaged in high-level R&D projects with the aim of improving existing technology and introducing new innovations in high-speed machining.

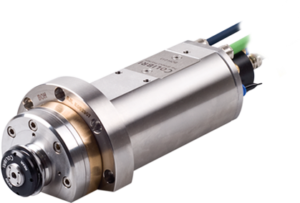

- High rotation speed enables high feed rate and reduced machining time

- Cutting tool dia. set according to the application

- Optimized cutting speed and real-time RPM monitoring

- High efficiency, precise and accurate table feed

- Up to 70% faster and more efficient compared to original machine spindle

Partnering for Success

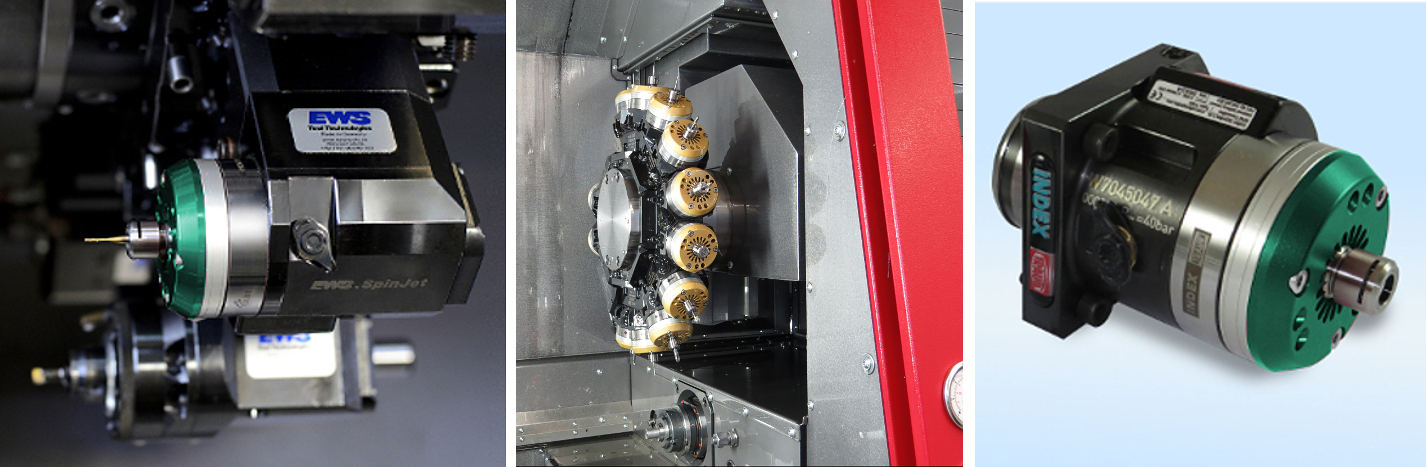

Colibri works in partnership with leading CNC machine and tool manufacturers, such as EWS Weigele GmbH & Co. KG and INDEX-Werke GmbH & Co. KG, in providing advanced manufacturing technology for a wide range of applications and processes, designed to maximize productivity and increase profitability for the end customer. See our partners

VIDEO >>> Milling Application on Lathe Machine by EWS: Coolant-Driven HSM Jet Spindle mounted on turret as active live tool.

Machining Applications

Contact Us

The HSM Jet Spindle is hard at work increasing productivity and profits in metalworking factories worldwide.

Contact us for further information about how our high-speed coolant-driven spindle technology can help you.