Jet Spindle Selection

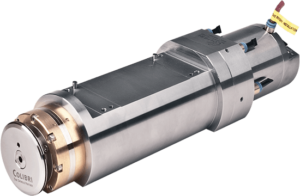

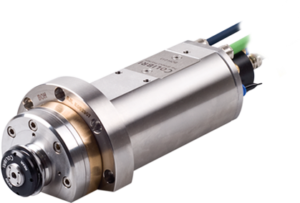

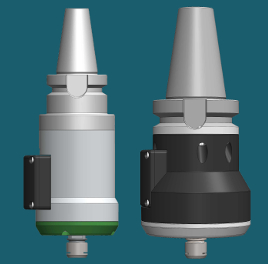

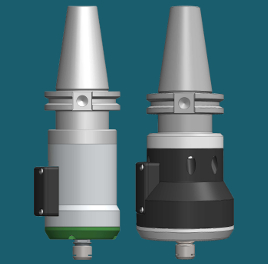

Two enhanced performance HSM Jet Spindle models ensure you’re getting the optimal solution for the widest range of machining applications using small cutting tools.The GreenJET Model and the HPC Model (high pressure).

Spindle selection is based on the following parameters:

- Machine coolant pressure

- Coolant flow rate

- Required rotational spindle speed

- Cutting tool diameter recommended:

0.4mm – 4.0mm (dependent upon the application)

GreenJET CNC Machine Prerequisites:

- Coolant flow through the main CNC machine spindle

- Min. coolant pressure, at main spindle outlet: 20 bar (290 psi)

- Max. coolant pressure, at main spindle outlet: 40 bar (580 psi)

- Minimum flow rate: 12 L/min (3.17 Gal/min.)

- Coolant filtration level: Max. 100 μm

- Coolant pressure measured at spindle inlet

HPC Model CNC Machine Prerequisites:

- Coolant flow through the main CNC machine spindle

- Min. coolant pressure, at main spindle outlet: 15 bar (218 psi)

- Max. coolant pressure, at main spindle outlet: 70 bar (1020 psi)

- Minimum flow rate: 16 L/min (4.23 Gal/min.)

- Coolant filtration level: Max. 100 μm

- Coolant pressure measured at spindle inlet

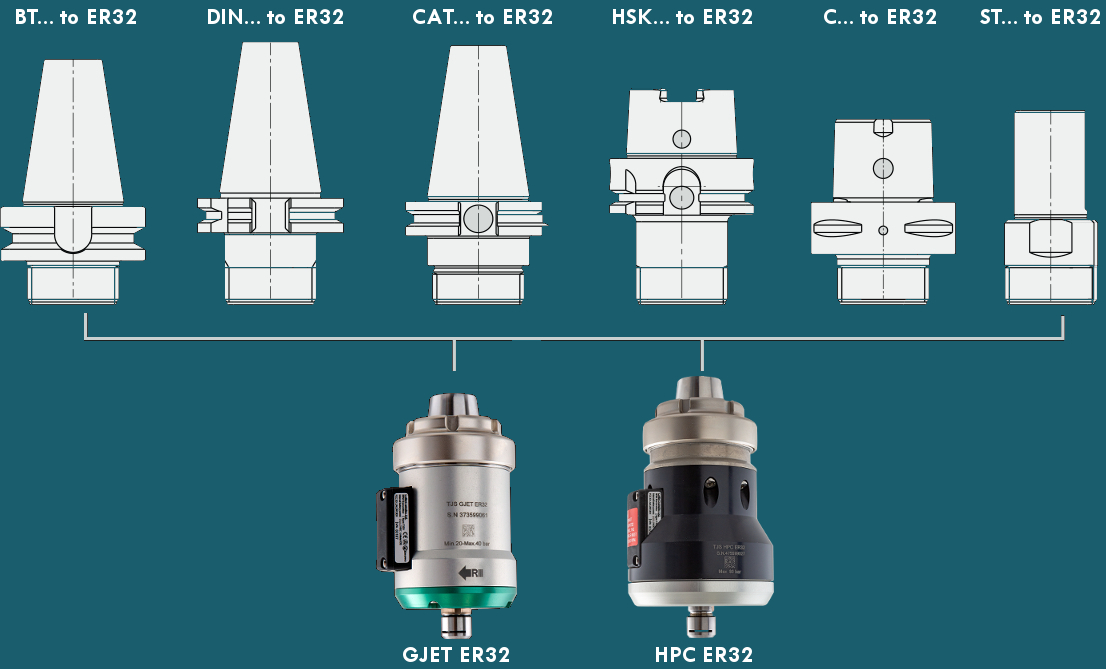

Adaptors & Clamping

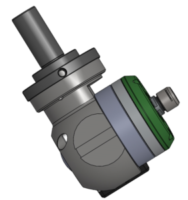

Modular Jet Spindles with

Built-in ER32 Collet

USING BT ADAPTOR MODELS: Internal diameter of the PULL STUD must be a min. of 4.0mm, to allow sufficient coolant pressure flow for proper Jet Spindle operation.

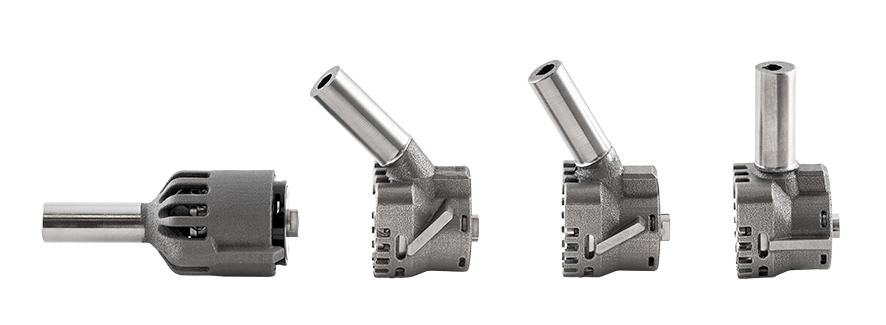

Integral Shanks

Cylindrical Shank

ST20

CAPTO 5 or 6 Shank

C5/6

HSK Shank

HSK A40 / A63

BT30 or 40 Shank

BT30/40

CAT 40 Shank

CAT 40

Package Contents