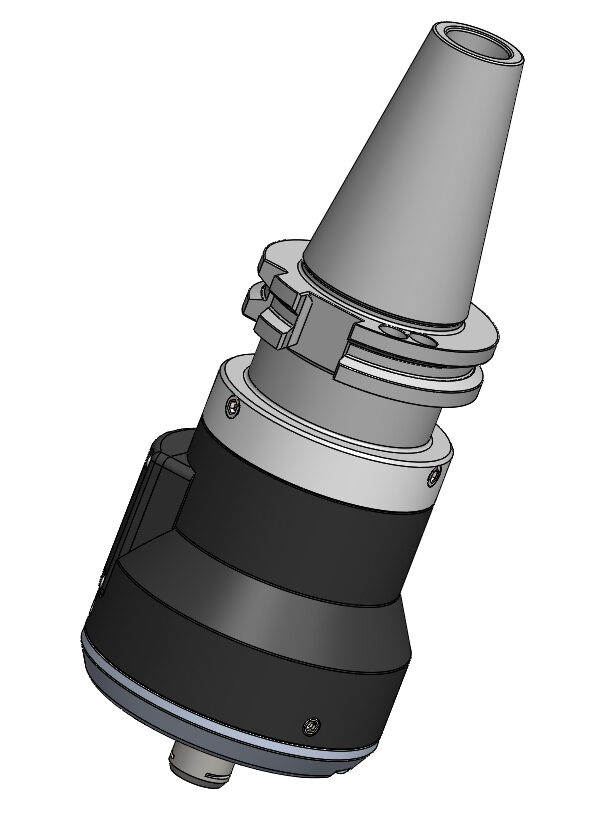

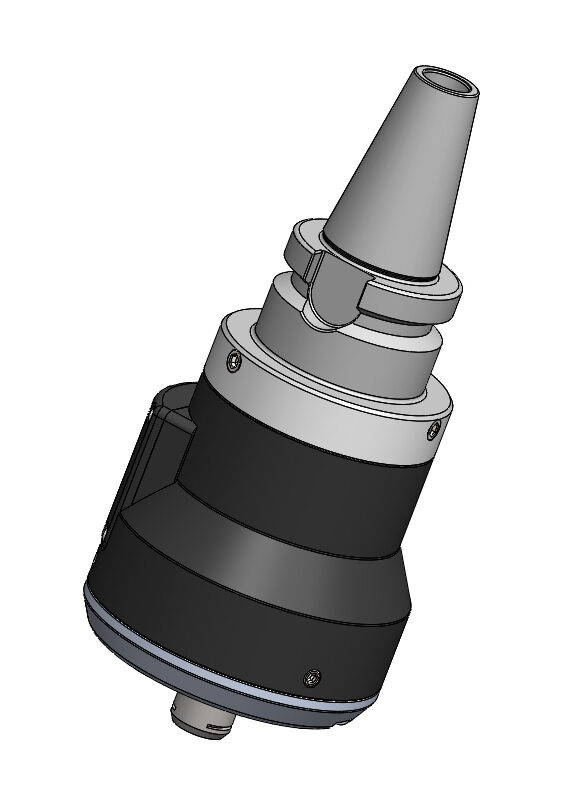

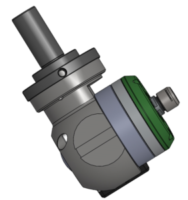

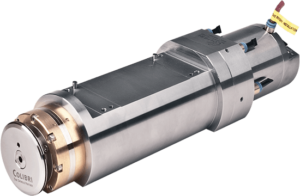

The High Power Coolant-Driven Jet Spindle (TJS-HPC) model, which uses the machine’s own coolant supply to drive the spindle, is the most powerful jet spindle for high speed machining in the world.

Ideal for machines with either lower or high pressure capabilities. The HPC Jet provides better machining results, longer tool life and increased efficiency with small tools on soft metals at 15 bar, small to medium tools on harden steel from 20 bar and with medium sized tools on soft metals. The spindle’s patented design is suitable for the growing number of machines in the market that use high pressure narrow beam coolant or high pressure coolant deep drilling tools.

• For finishing/semi-finishing using small to medium diameter cutting tools

• Plug & Play – no external feeds or pre-installation, fits ATC/turret

• On-board wireless RPM transmitter + external Display Unit/Monitor

| JET SPINDLE OPERATING PARAMETERS | TJS HPC | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| COOLANT | 15 BAR | 20 BAR | 40 BAR | 70 BAR | Terms of Use | ||||

| Supply Diameter | 4 mm | Collet | ER11 AA/UP | ||||||

| Flow Rate | 10 L/min | 12 L/min | 16 L/min | 20 L/min | Runout | 3 micron | |||

| Speed | 20,000 RPM | 25,000 RPM | 35,000 RPM | 45,000 RPM | Warranty | 1 Year | |||

| Max Power(W)/Torque(Nmm) | 53 / 20 | 71 / 27 | 188 / 57 | 409 / 93 | SMALL TOOL EXPERTISE REQUIRED | ||||

| Cutter [mm] | P | M | N | S | |||||

| Drilling | 0.1 – 2.0 | 0.1 – 2.0 | 0.1 – 3.0 | 0.1 – 2.0 | |||||

| Single / 2 / 4 Flute Helical, Corner Radii | 0.1 – 4.0 | ||||||||

| Ball-Nose [1] | 0.1 – 3.0 | ||||||||

| Chamfering [1] | 0.1 – 4.0 | ||||||||

| Lollipop [1] | 0.1 – 6.0 | ||||||||

| Barrel | 0.5 – 4.0 | ||||||||

| PCD Tipped | 0.1 – 3.0 | ||||||||

| Engraving [1] | 0.2 – 6.0 | ||||||||

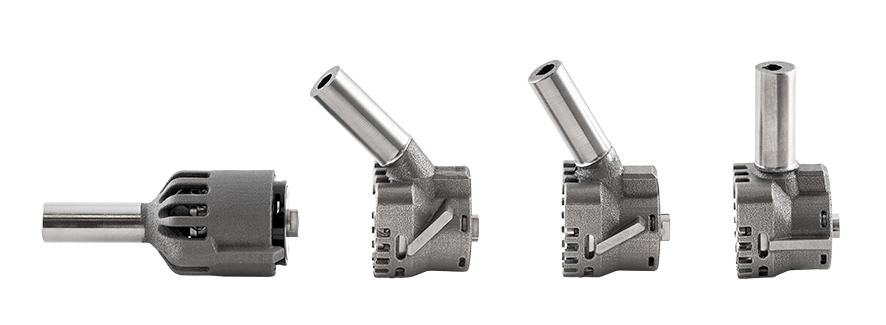

| ADAPTERS | ER32/ST20 | BT30/40/50 | HSK-63A/40A | SK30/40 | CAT 40/50 | C5/6 | |||

| [1] Effective DC (DCap) – Cutting diameter at cutting depth ap | |||||||||

- Coolant pressure is measured from the spindle inlet

- Rotational spindle speed is based on coolant pressure and flow rate

- Spindle speed may vary up to 7%

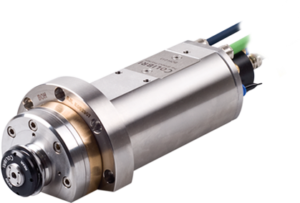

| HSM JETSPINDLE TYPE | TJS 20K | TJS 30K | TJS 40K |

|---|---|---|---|

| Operating Range Coolant Pressure [Bar] | 20~40 | 20~40 | 20~40 |

| Operating Range Coolant Flow Rate [L/min] | 12~18 | 12~18 | 12~18 |

| Rotational Spindle Speed [Krpm]* | 30k~45k | 35k~55k | 40k~60k |

| Optimum Tool Cutting Diameter [mm] | Drilling 0.5~2.0 Milling 1.0~3.5 | Drilling 0.5~2.0 Milling 1.5~3.5 | Drilling 0.5~1.0 Milling 0.5~1.2 |

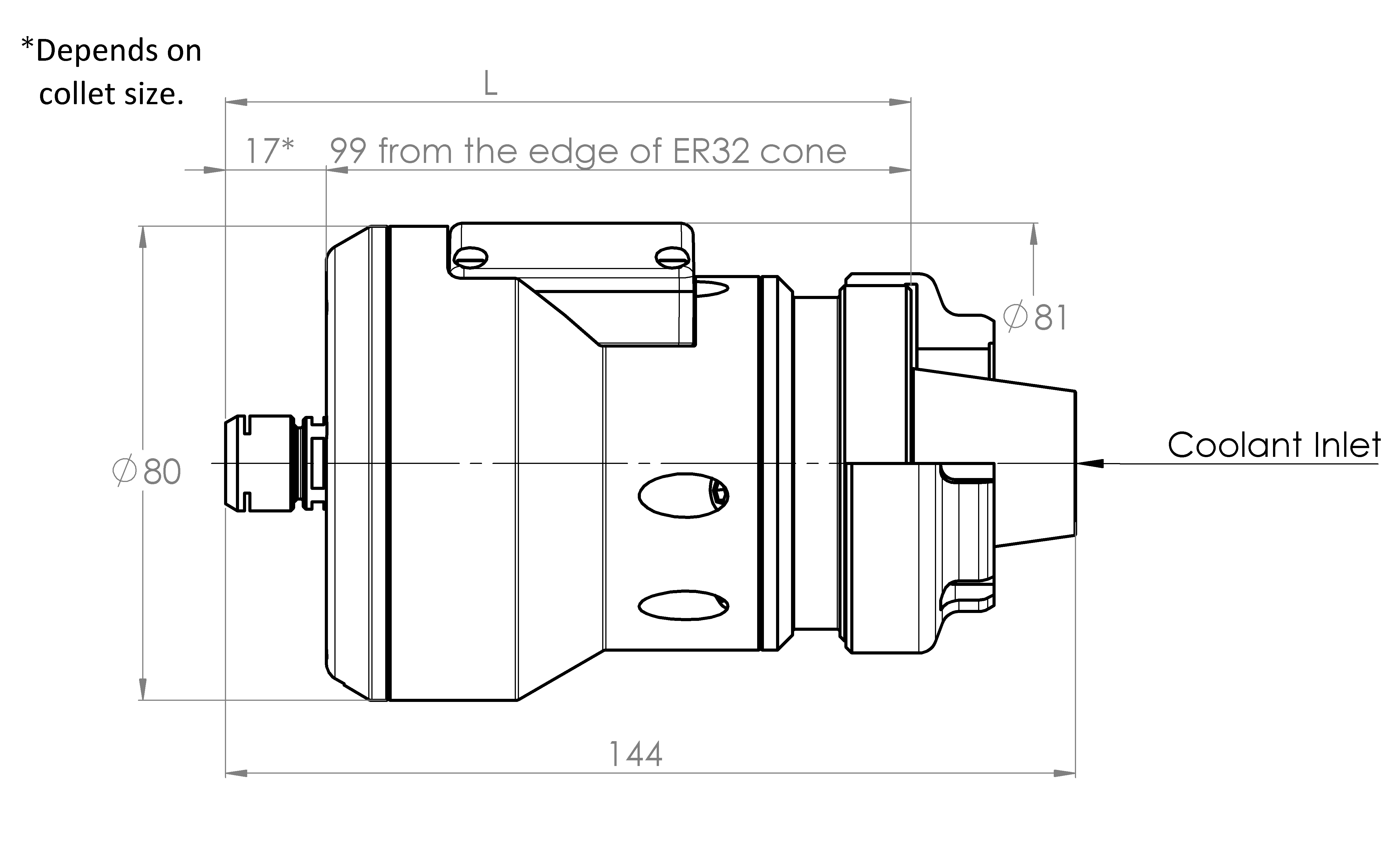

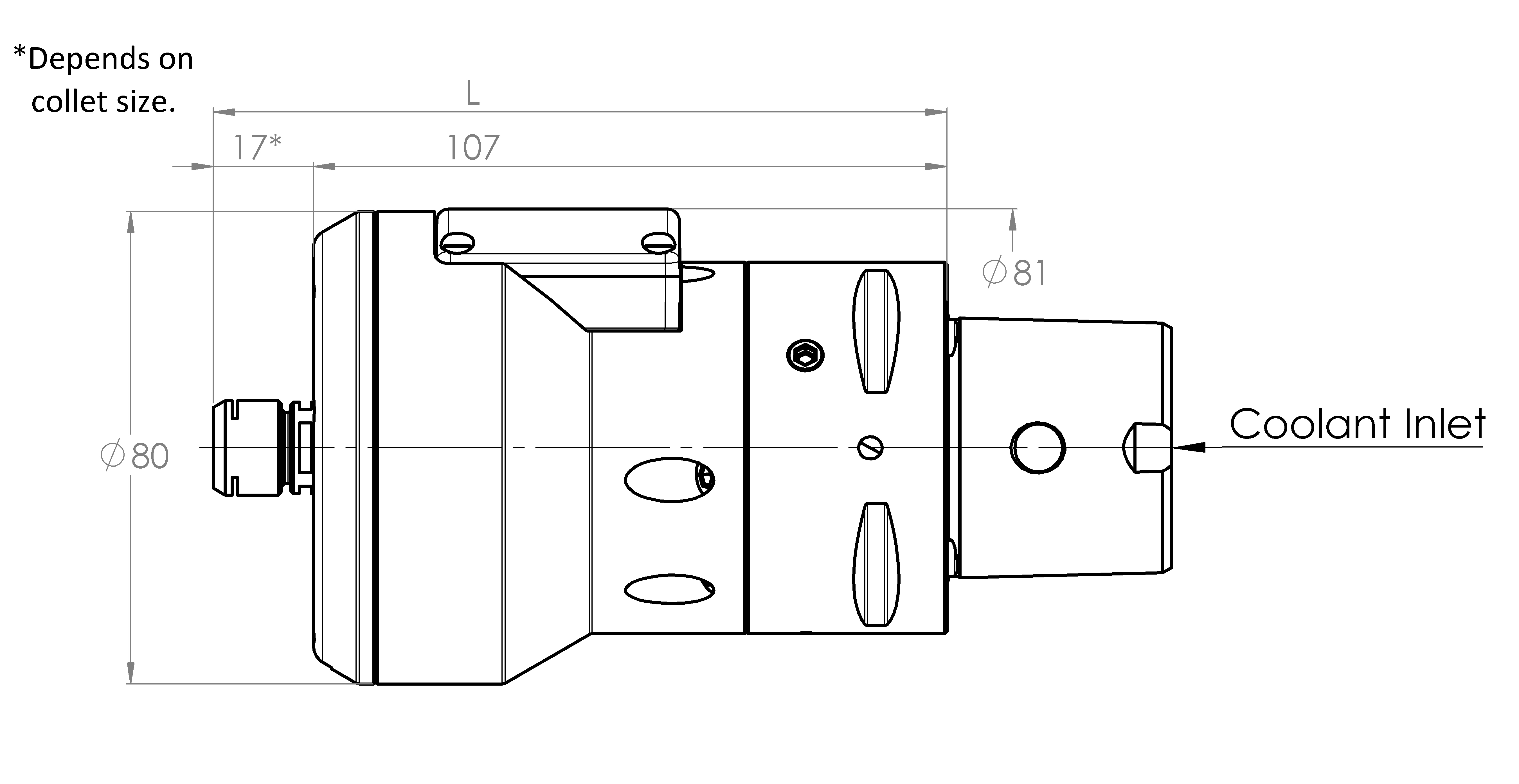

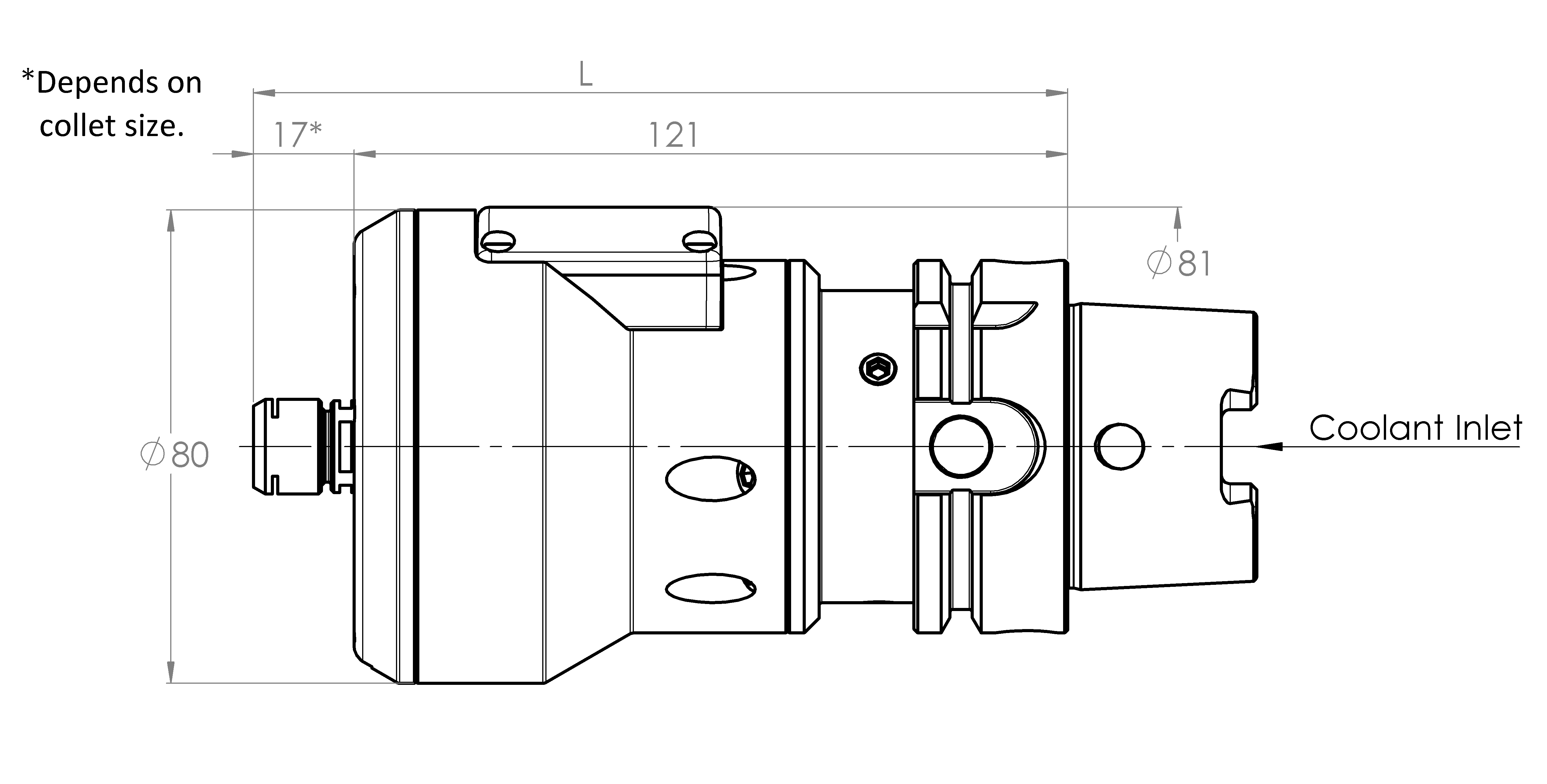

TJS-HPC: ER32

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC ER32 | 47-055-599 | ER32 | 116.00 | 4.0 | 1.70 |

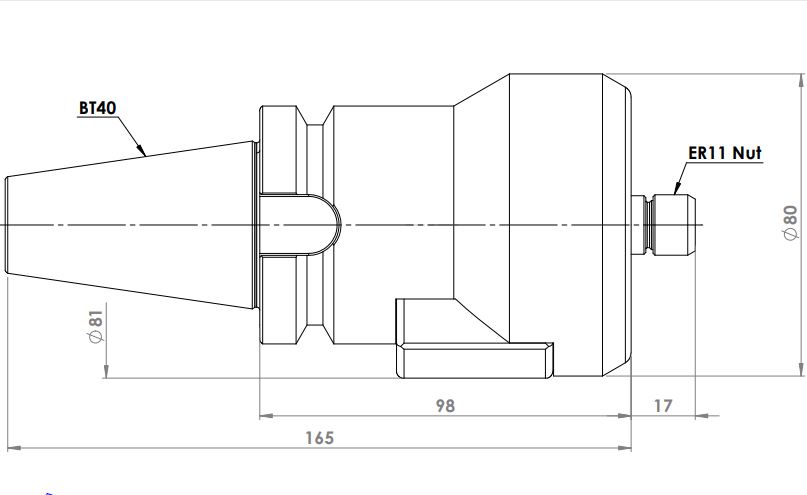

TJS-HPC: BT 40

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC BT40 | 47-055-799 | BT40 | 115.00 | 4.0 | 1.90 |

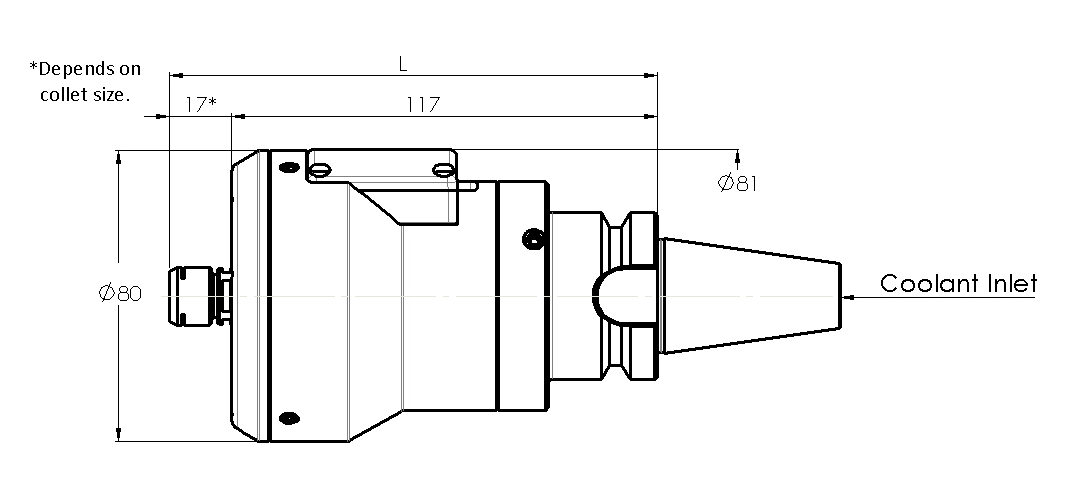

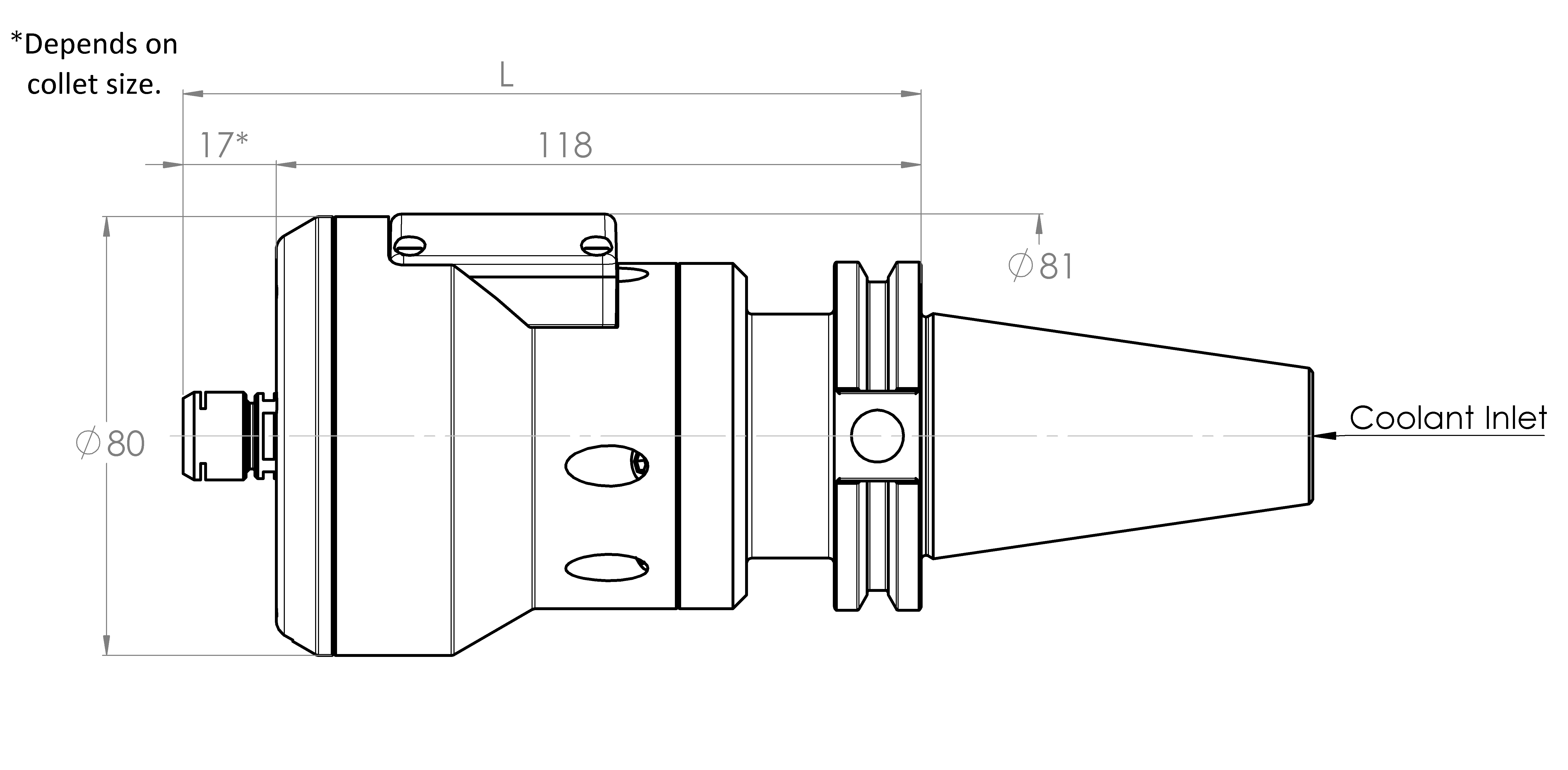

TJS-HPC: BT 30

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC BT 30 | 47-055-399 | BT30 | 136.00 | 6.0 | 2.00 |

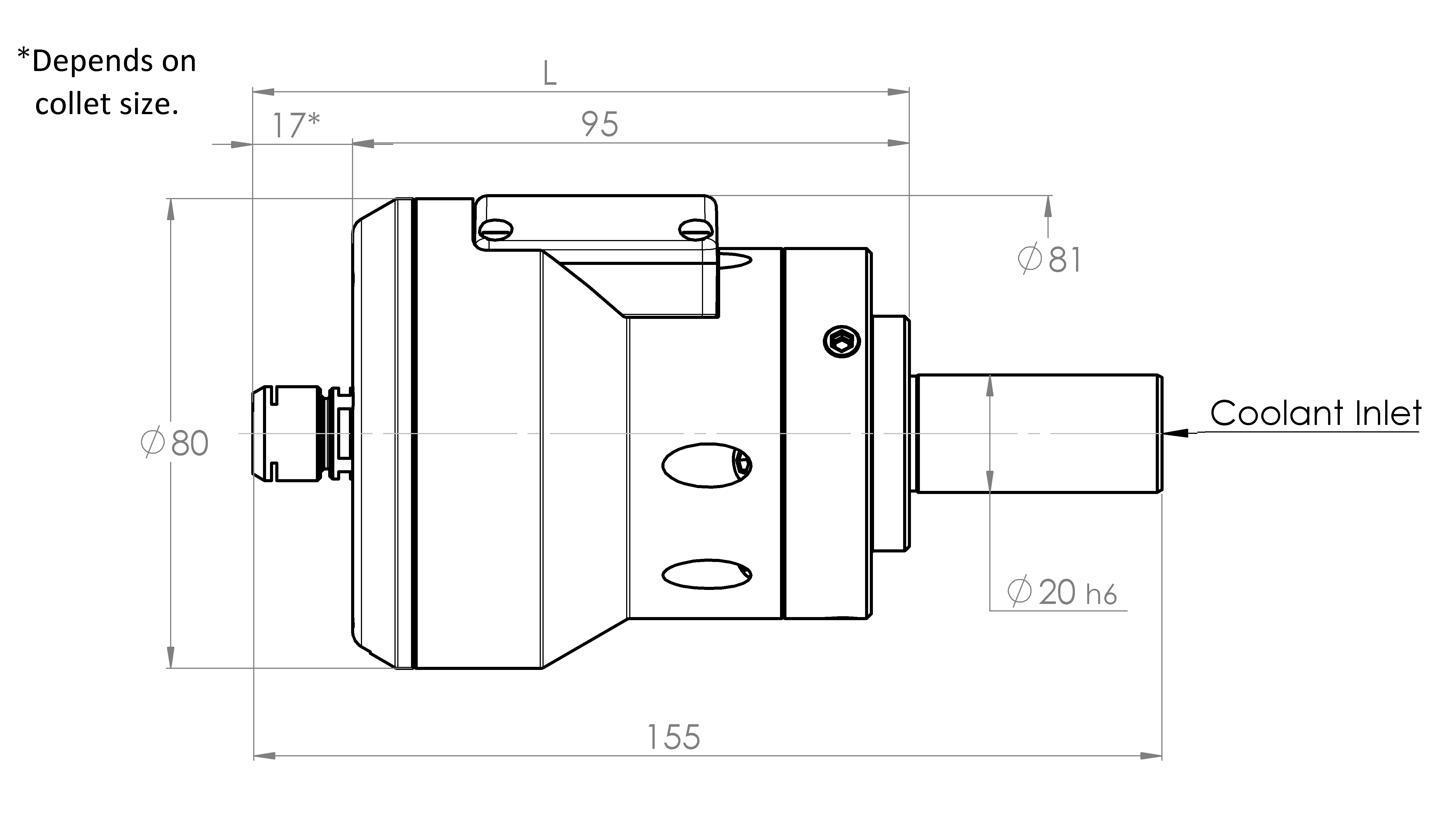

TJS- HPC: ST20

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC ST20 | 47-055-099 | ST20 | 112.00 | 4.0 | 1.5 |

TJS- HPC: C6

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC C6 | 47-055-199 | C6 | 124.00 | 4.0 | 2.0 |

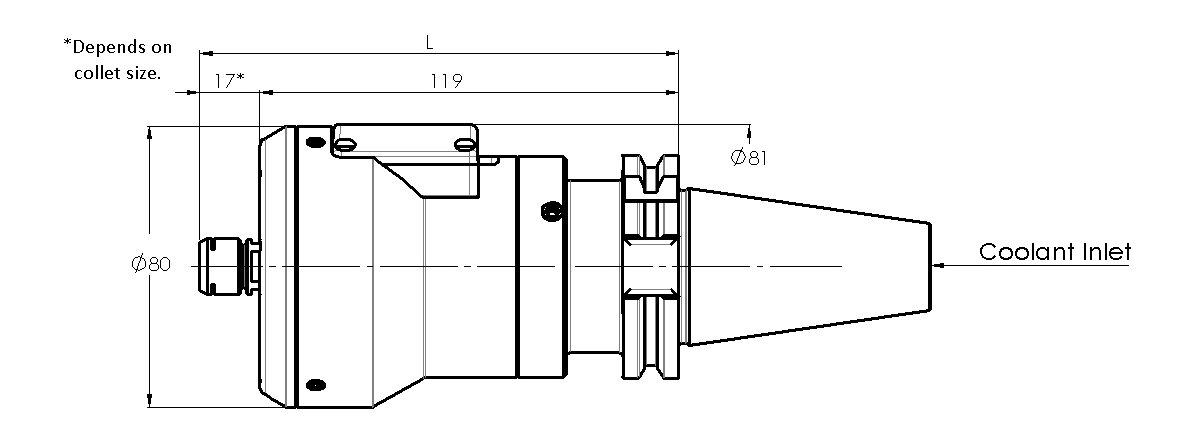

TJS- HPC: CAT 40

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC CAT 40 | 47-055-699 | CAT 40 | 135.00 | 4.0 | 2.3 |

TJS- HPC: SK40 DIN

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC SK40 | 47-055-699 | SK40 | 135.00 | 6.0 | 2.3 |

TJS- HPC: HSK A63

| Designation | P/N | Adaptor | L mm | Tool d max mm | Kg |

|---|---|---|---|---|---|

| TJS HPC HSK A63 | 47-055-299 | HSK A63 | 138.00 | 6.0 | 2.0 |

Colibri Spindle Products

Colibri Spindle Products